Category: Condition Monitoring

Jim Fitch authored articles & papers

-

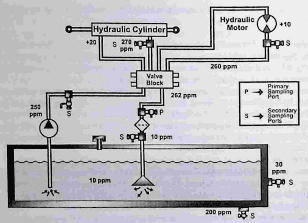

Advancements in Fluid Analysis Technologies and Strategies for Hydraulic SystemCondition-Based Maintenance

World-class condition monitoring of hydraulic systems involves the successful integration of a number of strategic elements. While in the past, walk-around inspections and gage data were the primary means of monitoring system health, today’s modem oil analysis programs apply a host of sophisticated new tools and instruments. Read More

-

Advantages of a Unified Condition Monitoring Approach

For most plants, condition monitoring consists of multiple technologies that are cobbled together in an attempt to enhance machine reliability. Clearly, these efforts are founded in good intentions, and many such programs enjoy considerable success. Still others languish due to a lack of symmetry and central focus. Money is spent and efforts expended, but results… Read More

-

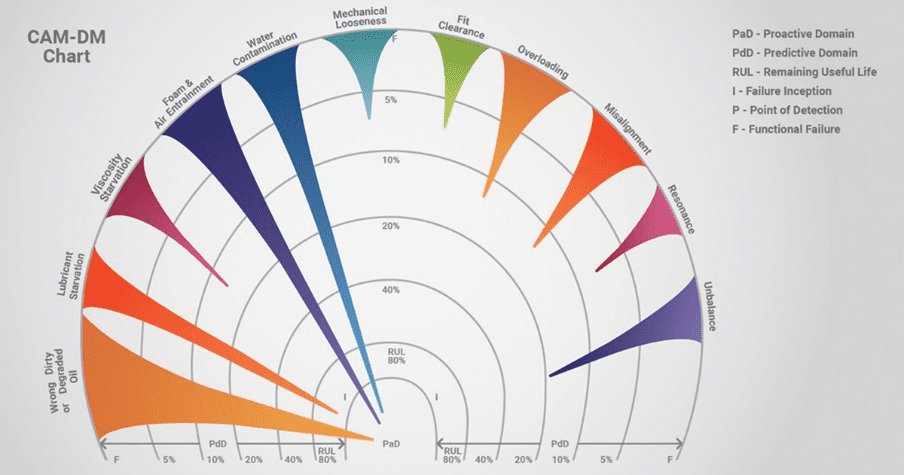

Introducing Condition Alarm Mapping (CAM)

The sheer number of infographics in the condition monitoring field is staggering; they show up on social media, and in conference presentations, whitepapers, websites and books. Infographics are effective at helping people comprehend difficult concepts that integrate an array of variables and factors. Read More

-

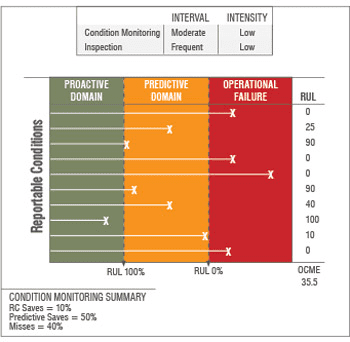

How to Measure the Effectiveness of Condition Monitoring

Condition monitoring should never be limited to a single technology or method. Instead, it should combine and integrate an optimum selection of purposeful tools and tasks. Condition monitoring can be largely technology based but can also be observation or inspection based. Read More

-

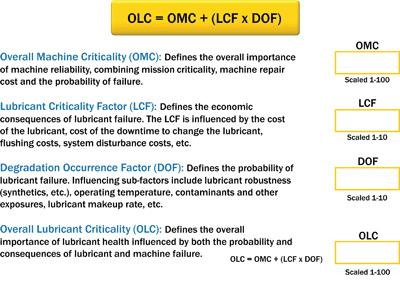

How to Select Machines for Oil Analysis

By Jim FitchMachinery Lubrication Magazine A few years ago, someone mentioned to me that many of his machines were not good candidates for oil analysis because they used little oil that wasn’t worth saving. He added that by the time you flushed the sampling port and pulled a proper oil sample, you’ve almost done an Read More

-

Lubricant-Based Techniques for the Condition Monitoring of Non-Circulating Gear and Bearing Systems

The best maintenance techniques for mechanical machinery are condition-based techniques. Condition-based maintenance is maintenance prescribed by the real-time needs of the machine according to changes in specific operation conditions. These conditions fall into two categories. Read More

-

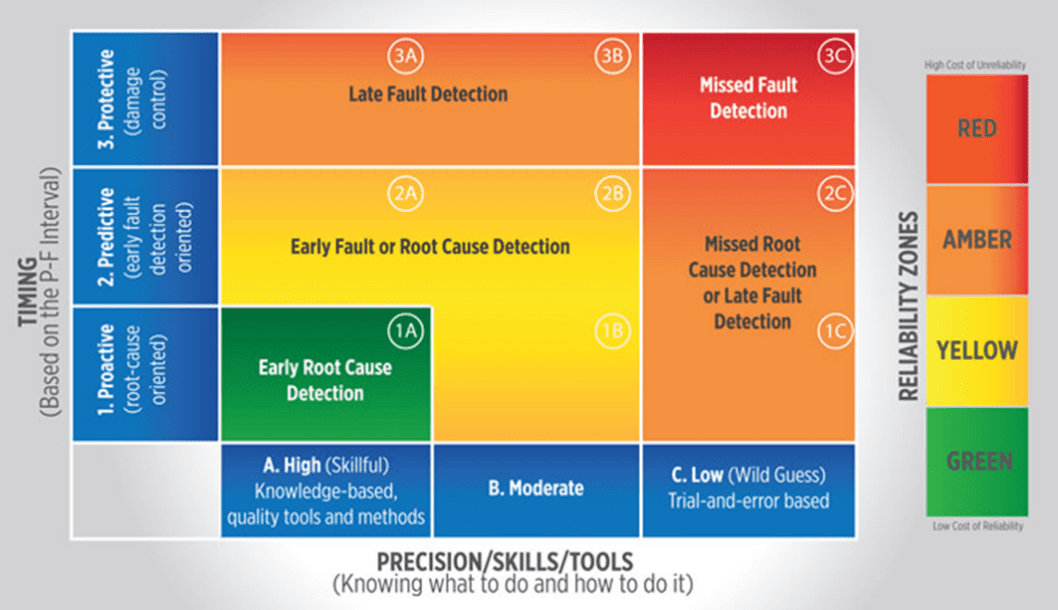

Detection Zone Coding for More Efficient Condition Monitoring

These days, reliability professionals are faced with diverse options related to technologies and methods to detect, troubleshoot and remediate problems. Figure 1 is a simple example of the available options to collect data and arrive at decisions regarding the health of machinery and machine components. Read More

-

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions: Read More

-

Lubricant-Based Techniques for Condition Monitoring of Non-Circulating Gear and Bearing Systems

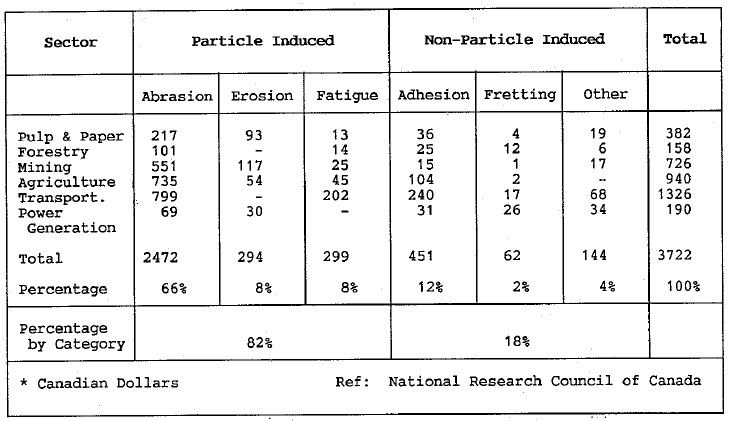

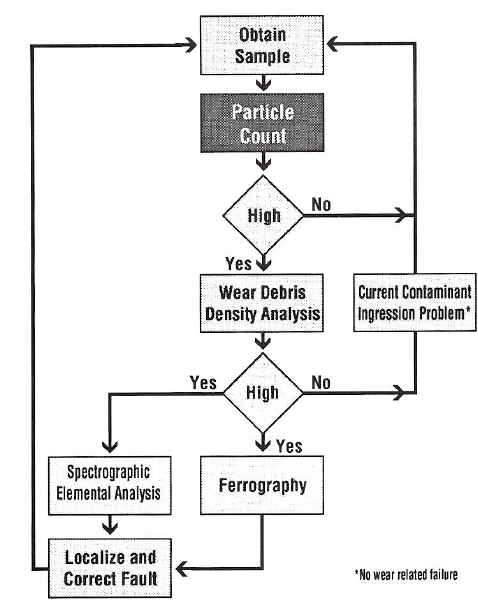

The majority of wear related failures occur as the direct result of particulate contamination. A recent article published in Lubrication Engineering magazine concludes that more than 82% of wear related losses are contaminant induced. Read More

-

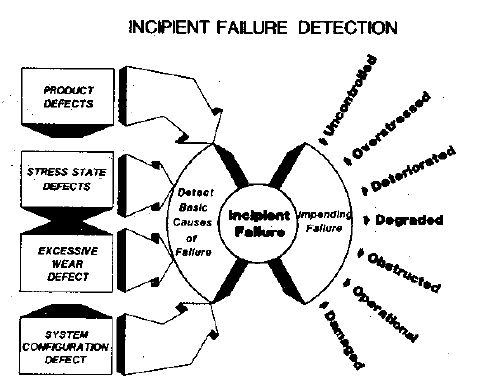

Systems and Methods for Real-Time Condition Monitoring of Mechanical Machinery

Catastrophic machinery failure in most cases can be avoided if the early symptoms are detected and appropriate action is taken. This is the essence of new condition monitoring technology which, if well conceived, can extend machine and component lives by as much as an order of magnitude. This paper discusses current condition monitoring methods including… Read More

-

Proactive Maintenance the Cost-Reduction Strategy

The field of maintenance technology going through a revolution of change. Gone are the t days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating lives many times that attainable just a few years ago. Read More

-

Proactive Maintenance, the Newest Buzz Word

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Read More