Category: Gears & Bearings Lubrication

Jim Fitch authored articles & papers

-

Silent Assumptions of Bearing Reliability

There are several important silent assumptions of bearing reliability. However, before I address these assumptions, some even more basic assumptions and statements of fact must be established. Read More

-

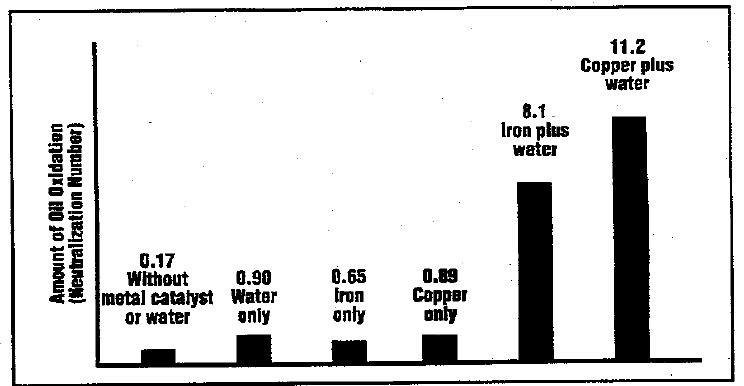

How Water Causes Bearing Failure

By Jim FitchMachinery Lubrication Magazine It takes only a small amount of water (less than 500 ppm) to substantially shorten the service life of rolling element bearings. There is a vast amount of research that supports this. Being a career-long crusader of clean and dry oil, I will certainly not argue the contrary. In fact, Read More

-

Aren’t Machines Supposed to Wear Out?

You’ve heard the expression. There are only two things in life that are certain: death and taxes. Some have suggested that the same applies to machinery. Read More

-

Moisture… the Second Most Destructive Lubricant Contaminant, and its Effects on Bearing Life

Water, once in an oil, is in constant search of a stable existence. _Unlike oil, the water molecule is polar, which greatly limits its ability to dissolve; and many additives have polar extremities which can markedly increase water solubility. Read More