Category: Wear Debris Analysis

Jim Fitch authored articles & papers

-

Deciphering Important Visual Features of Wear Particles

When working from a single sample, it is common for labs to classify wear particles according to standardized shapes such as platelets, chunks, ribbons and spheres. T Read More

-

Tricks to Classifying Wear Metals and Other Used Oil Suspensions

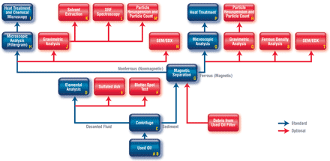

The most common methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. For some users, because of the criticality of the application, all of these screening tests for wear metals are integrated into the routine test slate. Read More

-

Best Practices in Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practiced in mobile equipment applications. Read More

-

Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practice in mobile equipment applications. However, these same techniques don’t always transfer successfully into stationary equipment applications for many users. Read More

-

Origin of Spherical Particles in Lubricants

Spherical particles have been found in microscopic analysis in many different machines. The phenomenon of perfectly round spheres has been a topic of interest since their discovery and a number of theories have been formulated for their origin. Read More

-

Tactics For Identifying Wear Metal and Solid-particle Suspensions

The most widely used laboratory methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. Read More

-

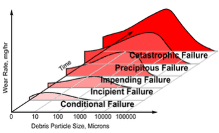

The Benefits of Using Wear Debris Analysis in Industrial Machinery

The analysis of powertrain lubricants for the purpose of detecting faults and abnormal wear patterns is a useful practice in mobile equipment applications. Unfortunately for many users, these techniques don’t always transfer successfully into stationary equipment applications. In recent years, new approaches and techniques have been advanced to improve the detection of incipient and developing… Read More

-

Virgin Particles and Weak Signals: Finding Meaning in Wear Debris

I often mention the wear debris universe when I lecture on oil analysis topics. This refers to the extensive array of wear particle technologies and tactics that can help reveal the true tribological condition of a machine. Read More