By Jim Fitch

Machinery Lubrication Magazine

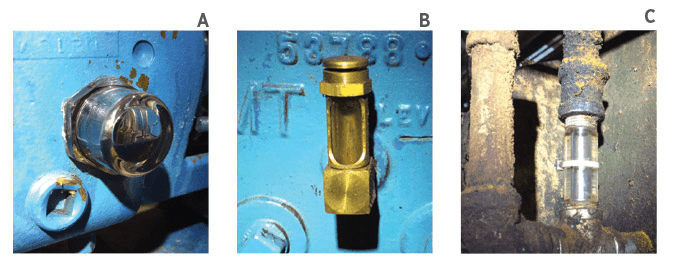

A sudden change in oil level, either up or down, is a telegraphed alert that something is wrong. And, this “something” could potentially be serious. Deferring maintenance or ignoring this alert could lead to a costly repair and longer downtime in the future. The frequent examination of quality oil level sight glasses by trained inspectors is a sound condition monitoring practice. Perhaps the most important of all lubrication-related inspections.

Whether oil goes up or down, any sudden change in the oil level requires troubleshooting in search of the cause and corrective action. Just adding more oil or removing excessive oil is an activity of treating the symptom, not the cause. True, some oil level changes are rather common and quickly understood. For instance, if oil goes sharply down, you might have a conspicuous leak (internal or external) that can be easily found and plugged.

Internal leakage occurs when a fluid has gone from one compartment to another. Leakage may be associated with seal failure or perhaps the wrong oil in use. Low viscosity oils leak faster than high viscosity oils. An abrupt chemical change in a lubricant can affects its interfacial tension which can increase the rate of leakage.

If the oil level goes up, this may be due to the introduction of new fluid. For example, perhaps someone added too much oil, or another fluid like a coolant or even fuel has entered the system, which has raised the oil level.