By Jim Fitch

Machinery Lubrication Magazine

Inspection 2.0 is rooted in some of the most fundamental and time-honored maintenance principles. One of them is total productive maintenance (TPM). Today, it’s hard to play an active role in the field of maintenance and reliability without encountering and embracing TPM. Honestly, it is delusional to think otherwise.

World-class maintenance organizations understand the intrinsic value of a well-tuned and culture-driven TPM program. World-class TPM programs are fundamentally powered by keen observation. You can’t fix what you can’t see. Therefore, all progress hinges on the power of observation. Allowing you to see is the bedrock. Improve the quality of inspection and, by default, you improve the quality of TPM and all the benefits that TPM seeks to achieve. It’s that simple!

The origin of TPM can be traced back to the Japanese automobile industry in the 1960s. It has many similar elements to the quality movement that was advanced in Japan during the same period. However, it wasn’t until 1988 that the western world learned of TPM when two seminal English texts were published on the subject by Seiichi Nakajima. From that point, TPM spread across the vast global maintenance and reliability landscape.

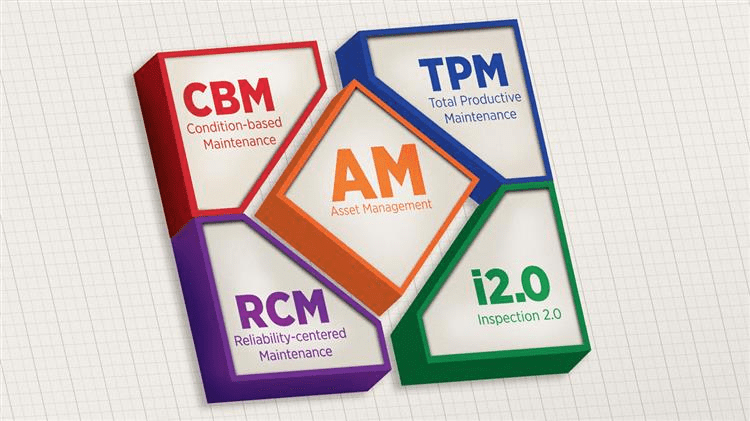

TPM has similarities and overlapping features with other branded maintenance philosophies, including reliability-centered maintenance (RCM), condition-based maintenance (CBM) and asset management (see Figure 1). However, its strongest difference is the active and responsible role of machine operators and small groups toward maintenance prevention and improved asset utilization.