By Jim Fitch

Machinery Lubrication Magazine

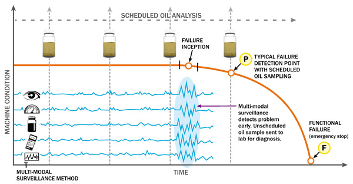

Most oil samples are taken based on a fixed schedule. For large, stationary rotating equipment, monthly or bi-monthly samples are common. Proactive maintenance programs depend on regular checks for oil cleanliness, dryness and lubricant quality.

However, machines can and do fail for a variety of reasons, and there is a certain randomness to the onset of these failures. Furthermore, the failure development period is equally unpredictable, with some failures taking months to develop, while others are sudden and abrupt.

In the March-April 2013 issue of Machinery Lubrication, I addressed machine criticality analysis as an essential tool to define the Optimum Reference State (ORS) for numerous lubrication and oil analysis activities. The Overall Criticality Matrix (OCM) is constructed from two assessments: the Machine Criticality Factor (MCF) and the Failure Occurrence Factor (FOF).

The MCF relates to the consequences of machine failure while the FOF relates to the probability of machine failure. Both the MCF and the FOF are highly influenced by the effectiveness of “early fault detection.” In other words, the effectiveness of early fault detection sharply reduces machine criticality (for details on this, read the article at www.machinerylubrication.com/Read/29346/machinery-criticality-analysis).