By Jim Fitch

Machinery Lubrication Magazine

For those who strive for lubrication-enabled reliability (LER), more than 95 percent of the opportunity comes from paying close attention to the “Big Four.” These are critical attributes to the optimum reference state (ORS) needed to achieve lubrication excellence. The “Big Four” individually and collectively influence the state of lubrication, and are largely controllable by machinery maintainers. They are well-known but frequently not well-achieved. The “Big Four” are:

- Correct lubricant selection

- Stabilized lubricant health

- Contamination control

- Adequate and sustained lubricant level/supply

The first three of the “Big Four” have benefited from considerable industry attention, especially in recent years. Conversely, the last one has gone relatively unnoticed yet is no less important. Therefore, it will be the central focus of this article.

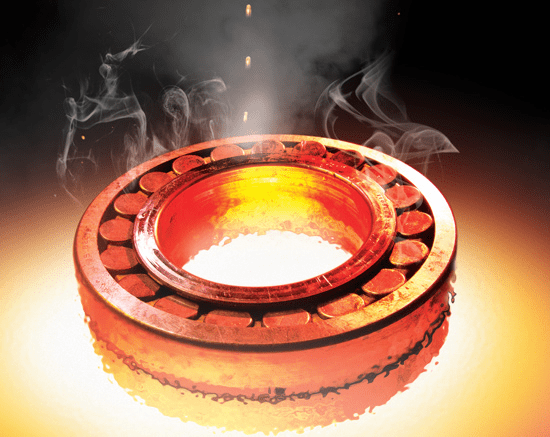

Over the past few decades, researchers and tribologists have compiled countless listings that rank the chief causes of machine failure. We’ve published many of these in Machinery Lubrication magazine. The lists ascribe the causes of abnormal machine wear to the usual suspects: contamination, overheating, misalignment, installation error, etc. There’s typically a lubrication root-cause category that is a catch-all for one or more causes that can’t be easily specified or named. I’ve seen terms used like “inadequate lubrication” and “wrong lubrication.”