By Jim Fitch

Machinery Lubrication Magazine

The designs of many common machine mechanisms have not changed significantly in decades (centuries in some cases). This is especially true where lubrication is involved. Apparently, machine designers working for original equipment manufacturers (OEMs) are under the impression that lubrication has not been, or simply cannot be, improved.

Sadly, there are new machines manufactured today based on this false premise. Conspicuous evidence of this is seen in many wet-sump oil systems found in pumps, gearing and bearings.

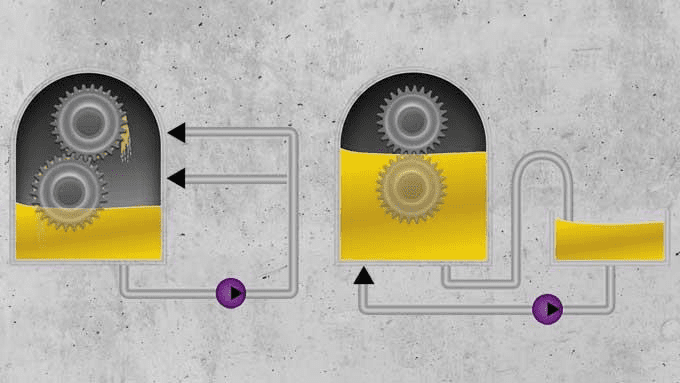

Good examples are the many non-circulating bearing and gear sumps that feed oil to frictional surfaces. These are wet-sump lubrication (WSL) systems that deliver lubricants using one of the following methods:

- Flood Lubrication — Frictional surfaces are submerged in a bath of oil.

- Slinger/Flinger Lubrication — Moving parts cup and toss oil to troughs and frictional zones.

- Oil Ring/Collar Lubrication — Rotating rings and collars lift oil to the top of channels and grooves where oil is fed into bearings by gravity.

- Splash Lubrication — Gear movement passing through an oil sump produces a splash or mist throughout the gearset to wet machine surfaces.

- Climbing-Oil Lubrication — Gears rotating through a wet sump lift clinging oil into gear mesh zones. Some use paddle gears to help lift and transfer oil to loaded gears.