By Jim Fitch

Machinery Lubrication Magazine

In the world of maintenance, there are two kinds of companies – those who are modernizing their maintenance programs and those who will. Companies on the trailing edge face one of two risks depending on their industry and geography:

Losing revenue to competition as demand for production capacity heats up.

Losing profits to competitors who export from low-cost labor markets abroad.

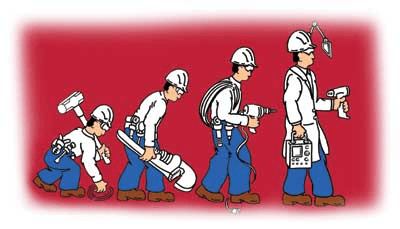

Averting these risks requires a process called change. Perhaps you’ve heard of it. Change can be evolutionary or revolutionary. Evolutionary change is incremental, more manageable and lower in risk.

However, for those laggards who have put off the inevitable, time may be running out. For them, the end to business- as-usual has arrived.

Catching up to already fast-paced competitors who are further along in the maintenance evolution may require sizeable short-term budgets for training, new tools and knowledge technologies.

Some of these companies may have to leapfrog over evolutionary and move straight to revolutionary. This would involve rapidly reinventing their work environment, maintenance practices, metrics and culture.

Instead of controlled and well-managed incremental improvements, breakthrough innovations may be required instead. Revolutionary change can be disruptive and often a source of stress and distress in the workplace.