By Jim Fitch

Coal Magazine

Equipment maintenance costs represent an unclaimed gold mine of savings opportunities. Yet deep maintenance cost reductions have evaded the efforts of even the most diligent and sophisticated operations. Why? Because there has been a general lack of emphasis on maintenance that corrects root causes, as opposed to responding to the symptoms or results of failure.

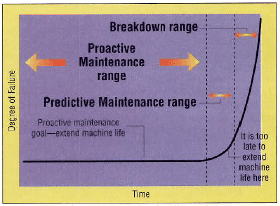

A shift in maintenance philosophy is needed, one that targets life extension and avoids the onset of component degradation.

The philosophy must not be reactive but proactive. A true proactive maintenance program must stabilize healthy, non-degrading, non-decaying, operating conditions by always being ahead of the first indication of failure.