Holly Borden & Jim Fitch

Proceedings of the Association of the Iron and Steel Industry Spring Conference

Recently, maintenance managers and corporate executives have shown a greater interest in rising maintenance costs and failure rates. The realization of the need to curb these costs has logically brought about the field of proactive maintenance. This is a program that concentrates on minimizing downtime and maximizing machine life.

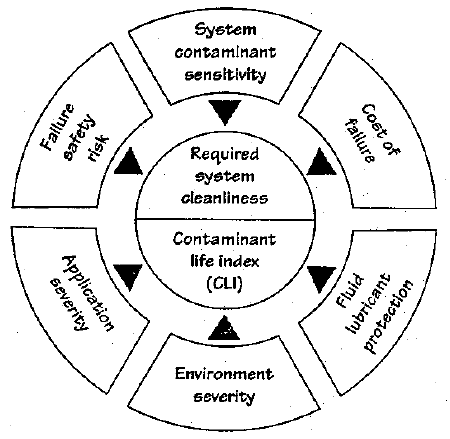

This paper discusses proactive contamination control for hydraulic and lubricating systems and describes its three step implementation process. Proactive maintenance begins with establishing appropriate cleanliness targets for each individual machine pursuant to machine specific criteria. This step sets the goal or benchmarks for each machine. The second step involves the process of selecting and implementing contaminant removal devices such as filters and separators necessary to” achieve the specified target cleanliness level. The final step is the routine monitoring of machine cleanliness at frequencies based on the previously established cleanliness target and the application conditions. This final step closes the loop and insures that “control” of fluid contaminant levels is achieved.