By Jim Fitch

P/PM Technology Magazine

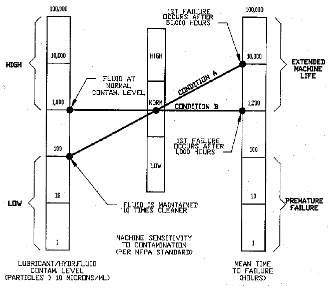

A proactive maintenance approach has been particularly successful in reducing or eliminating one of the most serious equipment maintenance problems: contamination of lubricant or hydraulic fluid systems. According to the bearings division of 1RW, “contamination is the number one cause of bearing damage that leads to premature removal.” Caterpillar states that “dirt and contamination are by far the number one cause of hydraulic system failures.” Similarly, J.I. Case states that “systems must be kept clean, spotlessly clean, in order to achieve the productivity they are capable of.” Finally, Oklahoma State University reports that when fluid is maintained 10 times cleaner, hydraulic pump life can be extended by 50 times (Fig. 1 ).

The most common types of contaminant induced failures in machinery are wear, sticking, seizure, erosion and corrosion. Contaminants can include solid particles, moisture, air, chemicals and other foreign materials. Figure 1 – Cleaner hydraulic fluid extends pump life.

The rate at which contamination enters a system is typically underestimated, and the effectiveness of filters in removing this contamination is often overstated. According to a study of hydraulic equipment at Oklahoma State University, “it has been demonstrated that apparent ingression rates of 10-100 million particles greater than 10 microns (per minute) characterize field systems (Figure 2).” Filters often have great difficulty removing these high contamination levels since they are subject to frequent changes in temperature, fluid viscosity, pressure, and flow; plus the effects of shock, vibration and fatigue. Other common problems are filter bypass valves that are stuck open, damaged or missing filter gaskets, and filters that are installed crooked or backwards.