-

Getting Machines to the Proper State of Inspection Readiness

I have written several articles on inspection recently, as I strongly believe it is foundational to condition monitoring, machine reliability and asset management. My last Machinery Lubrication column introduced the term “Inspection 2.0” to differentiate conventional inspection practices from the intense, probing and purposeful methods needed to optimize benefits. As common as inspection activities may… Read More

-

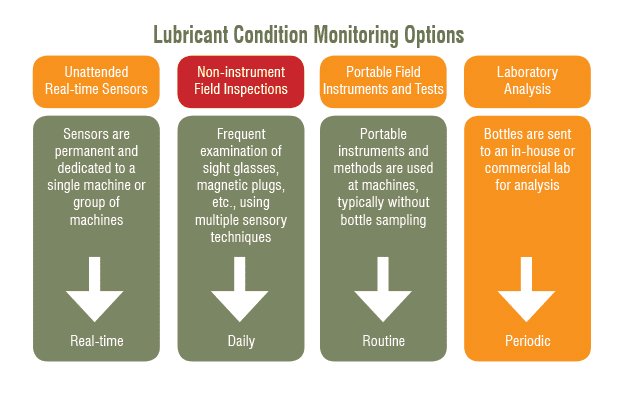

How to Visually Inspect the Health and State of Oil

The well-known KISS principle (keep it simple stupid) was first coined in the 1960s and began widespread use in the U.S. Navy shortly thereafter. While it started as a design principle for engineers, it has since been applied to any activity or creative endeavor that has had the propensity to become unnecessarily complicated. Read More

-

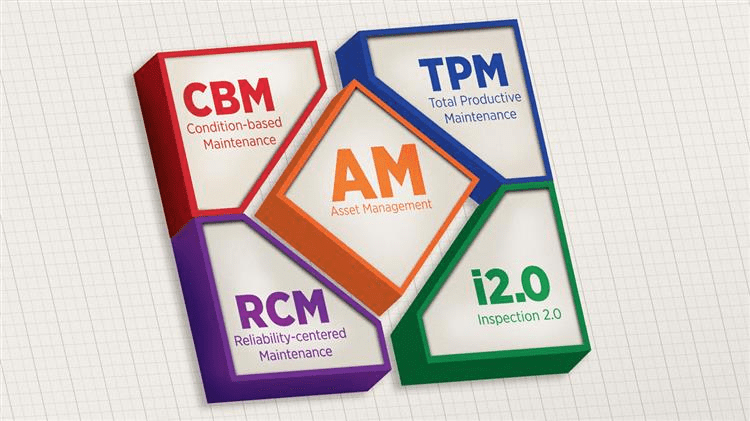

Inspection 2.0: The Cornerstone of World-Class TPM

Inspection 2.0 is rooted in some of the most fundamental and time-honored maintenance principles. One of them is total productive maintenance (TPM). Today, it’s hard to play an active role in the field of maintenance and reliability without encountering and embracing TPM. Honestly, it is delusional to think otherwise. Read More

-

The 5 States of Machine Inspection 2.0

When most of us refer to inspection, we are thinking of running machines inspected routinely, say on daily rounds. Unarguably, this type of on-the-run inspection is critical to machine condition monitoring, but other types of inspections are important as well. Read More