-

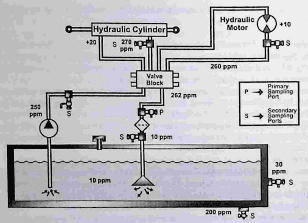

Advancements in Fluid Analysis Technologies and Strategies for Hydraulic SystemCondition-Based Maintenance

World-class condition monitoring of hydraulic systems involves the successful integration of a number of strategic elements. While in the past, walk-around inspections and gage data were the primary means of monitoring system health, today’s modem oil analysis programs apply a host of sophisticated new tools and instruments. Read More

-

Deciphering Important Visual Features of Wear Particles

When working from a single sample, it is common for labs to classify wear particles according to standardized shapes such as platelets, chunks, ribbons and spheres. T Read More

-

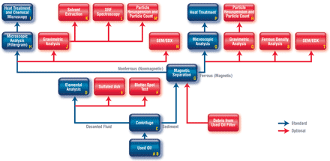

Tricks to Classifying Wear Metals and Other Used Oil Suspensions

The most common methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. For some users, because of the criticality of the application, all of these screening tests for wear metals are integrated into the routine test slate. Read More

-

Tactics For Identifying Wear Metal and Solid-particle Suspensions

The most widely used laboratory methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. Read More