-

Contamination Control Strategies for Planned Oil Cleanliness

Despite the good intentions of many organizations, real improvements in contamination control often remain an elusive concept. They know that invisible particles are one of the largest single contributors to progressive wear of machinery. Read More

-

An Introduction to Fluid Contamination Analysis

Oil contamination may be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial, and may be detrimental, to the performance of the oil and/or the operating machinery. Read More

-

Lubricant-Based Techniques for the Condition Monitoring of Non-Circulating Gear and Bearing Systems

The best maintenance techniques for mechanical machinery are condition-based techniques. Condition-based maintenance is maintenance prescribed by the real-time needs of the machine according to changes in specific operation conditions. These conditions fall into two categories. Read More

-

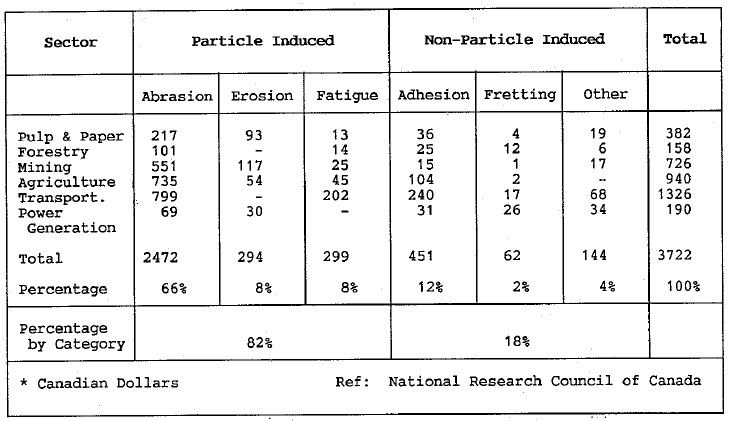

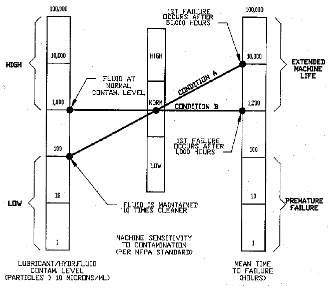

Particle Contamination — Both a Cause and a Result of Mechanical Failure

The monitoring of particle contamination in lubricating fluids is a critical indicator of incipient and impending failures. Recent research, under both laboratory and field conditions of the contaminant sensitivity of bearings, reveals a well defined cause and effect relationship between contaminant levels and relative machine life. Read More

-

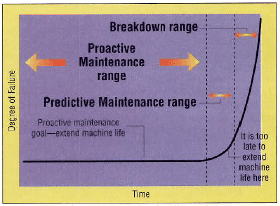

Proactive Maintenance – The New Technology for Cost-Efficient Contamination Controlof Mechanical Machinery

It has been proven that almost all mechanical failures are caused by contamination; hard particle contamination to be ·specific. Once the root cause of machine failure has been defined, a program to correct these failures, extend machine life, and reduce maintenance costs must be developed. Such a program has been developed; it is called Proactive… Read More

-

A New Approach to Maintaining Industrial Equipment

Costly particulate contamination slowly degrades and jams machine components causing product defects, shorter machine life., increased production downtime and decreased energy efficiency. Read More

-

Contaminant Monitoring Targets Root Causes of Machinery Problems

A proactive maintenance approach has been particularly successful in reducing or eliminating one of the most serious equipment maintenance problems: contamination of lubricant or hydraulic fluid systems. Read More

-

Fluid Contamination Analysis as a Maintenance Tool

Oil contamination can be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial and may even be detrimental to the performance of the oil and/or operating machinery. Read More

-

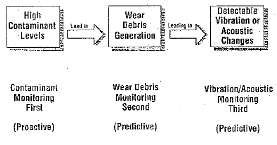

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions: Read More

-

Proactive Maintenance is a Blueprint for Success

It can take just one breakdown of a critical machine to spin an entire plant into an immediate production halt. At this point, it is too late for the plant manager to do anything but call a service technician, then gasp for air while counting the lost production. Read More

-

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. Read More

-

Proactive maintenance targets extending machine life

Equipment maintenance costs represent an unclaimed gold mine of savings opportunities. Yet deep maintenance cost reductions have evaded the efforts of even the most diligent and sophisticated operations. Why? Because there has been a general lack of emphasis on maintenance that corrects root causes, as opposed to responding to the symptoms or results of failure. Read More