-

Four Lethal Diesel Engine Oil Contaminants

Some contaminants are important to monitor and analyze because they are root causes of premature oil degradation and engine failure. Other contaminants are symptomatic of an active failure condition that requires a response other than just an oil change. Read More

-

The Hazards of Water Contamination in Oil

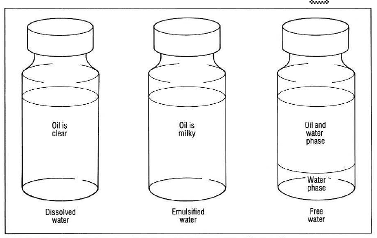

Most of us are well aware of the enormous damage water can exact on a machine and its lubricants. However, the magnitude of this potential destruction seems to depend directly on five enabling factors. These factors are listed below and are further diagramed in Figure 1. Read More

-

Filtering water from hydraulic oil

Water in a hydraulic system constitutes a serious form of oil contamination. However, water contamination is rarely recognized as such, hardly understood, and, until recently, considered difficult to combat. Read More

-

Filters can Remove Water from Hydraulic Fluid

Here is the latest component for hydraulic system filtration and contamination control Water is a very serious contaminant in oil hydraulic systems. Yet, water contamination is rarely identified, poorly understood, and, until recently, considered very difficult to remove. Read More

-

Lubricant-Based Techniques for Condition Monitoring of Non-Circulating Gear and Bearing Systems

The majority of wear related failures occur as the direct result of particulate contamination. A recent article published in Lubrication Engineering magazine concludes that more than 82% of wear related losses are contaminant induced. Read More

-

Standby Equipment Oil Monitoring and Maintenance

Many lubricants residing in standby equipment have only a few hours of service life. These few hours may be only from occasional scheduled restarts, typically circulating the oil at low load, sometimes barely warming it to operating temperature. In other cases, standby, laid-up and peak-load equipment may sit for weeks or even months without use. Read More

-

Filters can remove the water from hydraulic oil

Water in a hydraulic system constitutes a very serious form of oil contamination. Technically, water contamination is rarely recognized as such, poorly understood, and, until recently, considered difficult to combat. Read More

-

Filters kunnen het water uit hydraulische olie verwijderen (Filters can remove the water from hydraulic oil)

Water in a hydraulic system constitutes a very serious contaminant of the oil. Nevertheless, water contamination itself is rarely recognized, poorly understood, and until recently, considered difficult to combat. Read More