-

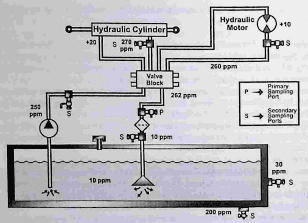

Advancements in Fluid Analysis Technologies and Strategies for Hydraulic SystemCondition-Based Maintenance

World-class condition monitoring of hydraulic systems involves the successful integration of a number of strategic elements. While in the past, walk-around inspections and gage data were the primary means of monitoring system health, today’s modem oil analysis programs apply a host of sophisticated new tools and instruments. Read More

-

Hydraulic Fluid Analysis: Avoiding the Potential Pitfalls

Analysis of hydraulic fluids, if done properly, can suggest maintenance procedures to improve hydraulic equipment reliability and extend system life. Significant cost savings can result. Read More

-

Elements of a Successful Oil Analysis Program – Part I & II

Most often, users associate an oil analysis program with a systematic early alert to oil or machine failure, i.e., damage control. While these benefits are helpful and frequently achieved, they should be regarded as low on the scale of importance compared to the more rewarding objective of failure avoidance. Read More

-

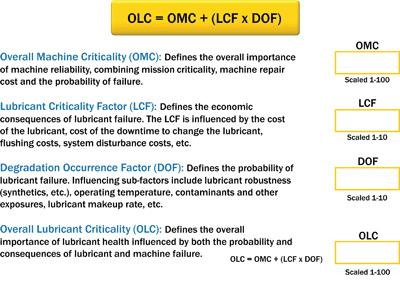

How to Select Machines for Oil Analysis

By Jim FitchMachinery Lubrication Magazine A few years ago, someone mentioned to me that many of his machines were not good candidates for oil analysis because they used little oil that wasn’t worth saving. He added that by the time you flushed the sampling port and pulled a proper oil sample, you’ve almost done an Read More

-

Oil Sampling Mistakes to Avoid

I recently received an e-mail from a colleague seeking my opinion about a specific sampling philosophy. Referring to mobile equipment such as excavators, scrapers and dozers, he asked if good oil sampling depended much on sampling location. Read More

-

The Basics of Used Oil Sampling

Proper oil sampling is critical to an effective oil analysis program. Without a representative lube sample, oil analysis cannot be used effectively to monitor oil condition, predict machine failures or help you extend asset life. Read More

-

The Ten Most Common Reasons Why Oil Analysis Programs Fail & the Strategies That Effectively Overcome Them (booklet)

Many have read the well-documented case studies that convincingly demonstrate the practice of used oil analysis as a sound approach to reduce maintenance and downtime costs. However, for most users, these rewards have evaded their best efforts due to common implementation errors. Like many pursuits in life, there is often a very fine line that… Read More

-

In Search of a Definition – What is Oil Analysis?

The term “oil analysis” has been used with respect to lubrication and machine reliability since the 19th century. Yet, over the years I have seen only a few attempts to assign a specific definition to the activity despite its widespread application in industry. Most of these definitions are too narrow or fail to include important… Read More

-

Measure by Measure [oil analysis in machine condition monitoring]

By some estimates, condition monitoring has been around for more than a century, but it is only within the last 5-10 years (and particularly the last 2 or 3) that interest has been at fever pitch. Read More

-

Six Questions Every Lube Tech Should Be Able to Answer Correctly

We’ve addressed the virtues of training numerous times on the pages of Machinery Lubrication and other Noria publications. Still today, we encounter a national workforce in the lubrication field that seems largely oblivious to many of the fundamental concepts that embody excellence in the profession. Read More