-

Blotter Spot Testing for Metallic and Other Solid Particles

The blotter spot test has been discussed numerous times in the pages of Machinery Lubrication magazine. It not only is one of the oldest oil analysis tests (mid-19th century) but endures as one of the most effective at detecting and even quantifying certain lubricant abnormalities. Read More

-

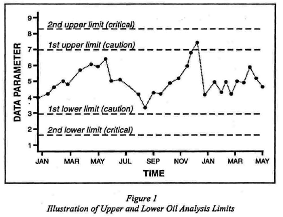

Proactive and Predictive Strategies for Setting Oil Analysis Alarms and Limits

Abstract: In oil analysis, well placed alarms and limits are like trip wires, alerting operators and technicians to an untoward or threatening condition. Oil analysis limits can vary considerably according to machine type, oil type, and reliability goals. This paper discusses four distinct types of limits and how they are applied to different machine and… Read More

-

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

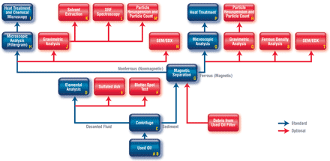

Tactics For Identifying Wear Metal and Solid-particle Suspensions

The most widely used laboratory methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. Read More

-

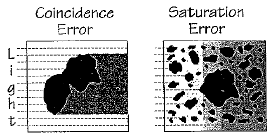

The Accuracy and Reliability of Optical Particle Counters with Industrial Oils and Hydraulic Fluids

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

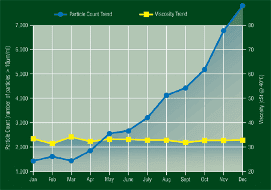

What Do You Do with a High Particle Count?

In recent years, I’ve been part of numerous investigations relating to expensive machine failures preceded by oil samples that registered high particle counts. Each time I asked the asset owner, my client, why the aberrant particle trends were not investigated further. In most cases the response was that they didn’t think it merited the extra… Read More

-

Comparison of Particle Counts Between Eight Commercial Oil Analysis Laboratories

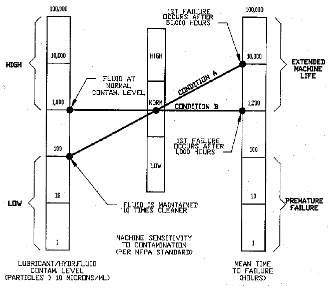

The inclusion of particle counting in the periodic analysis of hydraulic and lubricating fluids has provided an important new advancement to machine diagnostics. With particle counting, machinery users can monitor the principal cause of failure, not just the symptoms, or results, of failure. The benefit, when particle levels are controlled, is extended machine life and… Read More

-

Contaminant Monitoring Targets Root Causes of Machinery Problems

A proactive maintenance approach has been particularly successful in reducing or eliminating one of the most serious equipment maintenance problems: contamination of lubricant or hydraulic fluid systems. Read More

-

Deploying the Invisible Filter

To some contamination control might seem a little like an old tune. After all, hasn’t filtration been around nearly as long as lubrication? And, what’s new that hasn’t already been thoroughly explored and widely applied? Read More

-

Diesel Engine Oil Particle Counting Methods

In condition monitoring, any property that is important to machine reliability and life extension should be a property that is measured, assuming it is technically and economically feasible. Read More

-

Fluid Contamination Analysis as a Maintenance Tool

Oil contamination can be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial and may even be detrimental to the performance of the oil and/or operating machinery. Read More

-

Particle Contamination – 10 Important Things You Should Know

This isn’t your usual article on how important clean oil is to lubricant health and machine reliability. Yes, we are going to talk about particle contamination, but we’re going to take a much closer look at the destructive traits of this nearly invisible material that cohabitates with our lubricants. Read More

-

Virgin Particles and Weak Signals: Finding Meaning in Wear Debris

I often mention the wear debris universe when I lecture on oil analysis topics. This refers to the extensive array of wear particle technologies and tactics that can help reveal the true tribological condition of a machine. Read More