-

Best Practices in Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practiced in mobile equipment applications. Read More

-

Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practice in mobile equipment applications. However, these same techniques don’t always transfer successfully into stationary equipment applications for many users. Read More

-

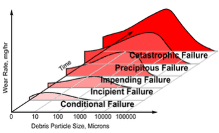

The Benefits of Using Wear Debris Analysis in Industrial Machinery

The analysis of powertrain lubricants for the purpose of detecting faults and abnormal wear patterns is a useful practice in mobile equipment applications. Unfortunately for many users, these techniques don’t always transfer successfully into stationary equipment applications. In recent years, new approaches and techniques have been advanced to improve the detection of incipient and developing… Read More

-

Particle Contamination – 10 Important Things You Should Know

This isn’t your usual article on how important clean oil is to lubricant health and machine reliability. Yes, we are going to talk about particle contamination, but we’re going to take a much closer look at the destructive traits of this nearly invisible material that cohabitates with our lubricants. Read More

-

Virgin Particles and Weak Signals: Finding Meaning in Wear Debris

I often mention the wear debris universe when I lecture on oil analysis topics. This refers to the extensive array of wear particle technologies and tactics that can help reveal the true tribological condition of a machine. Read More