-

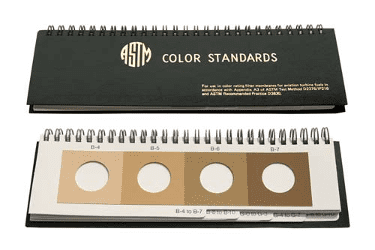

Blotter Spot Testing for Metallic and Other Solid Particles

The blotter spot test has been discussed numerous times in the pages of Machinery Lubrication magazine. It not only is one of the oldest oil analysis tests (mid-19th century) but endures as one of the most effective at detecting and even quantifying certain lubricant abnormalities. Read More

-

How to Spot Check Your Car’s Oil

Even the very best motor oils cannot safeguard against sludge when free water is present. Within several minutes after starting an engine, the oil typically reaches the thermostat setting. Read More

-

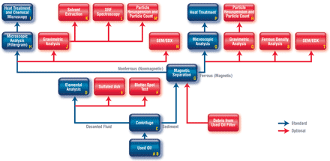

Tactics For Identifying Wear Metal and Solid-particle Suspensions

The most widely used laboratory methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. Read More

-

The Power of the Patch (Comparing particle analysis methods using membranes)

The practice of transferring suspended particles to the surface of a membrane for analysis has been around for decades. It is perhaps the earliest method for inspecting solid contaminants and wear debris in a used sample of oil. It is of no surprise that these methods have enduring use today. In fact, some are the… Read More

-

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. Read More

-

Looking Through the Eyes of Onsite Contaminant Monitors

Without the lens of a microscope, bacteria and viruses might only be recognized as painful symptoms of sickness and disease by those who are infected. Just as technology is an important enabler in human pathology, it also serves in the detection and diagnosis of a host of machine health issues, including the invasion of lubricant… Read More