-

Tricks to Classifying Wear Metals and Other Used Oil Suspensions

The most common methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. For some users, because of the criticality of the application, all of these screening tests for wear metals are integrated into the routine test slate. Read More

-

Best Practices in Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practiced in mobile equipment applications. Read More

-

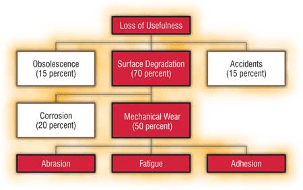

How and Why Machines Wear Out

According to Massachusetts Institute of Technology professor emeritus and luminary tribologist Ernest Rabinowicz, there are three things that cause machines to lose their usefulness: obsolescence, accidents and surface degradation. Without question, obsolescence is fundamental to the evolution of engineering and technology. Read More

-

Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practice in mobile equipment applications. However, these same techniques don’t always transfer successfully into stationary equipment applications for many users. Read More

-

The Benefits of Using Wear Debris Analysis in Industrial Machinery

The analysis of powertrain lubricants for the purpose of detecting faults and abnormal wear patterns is a useful practice in mobile equipment applications. Unfortunately for many users, these techniques don’t always transfer successfully into stationary equipment applications. In recent years, new approaches and techniques have been advanced to improve the detection of incipient and developing… Read More

-

Aren’t Machines Supposed to Wear Out?

You’ve heard the expression. There are only two things in life that are certain: death and taxes. Some have suggested that the same applies to machinery. Read More

-

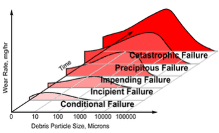

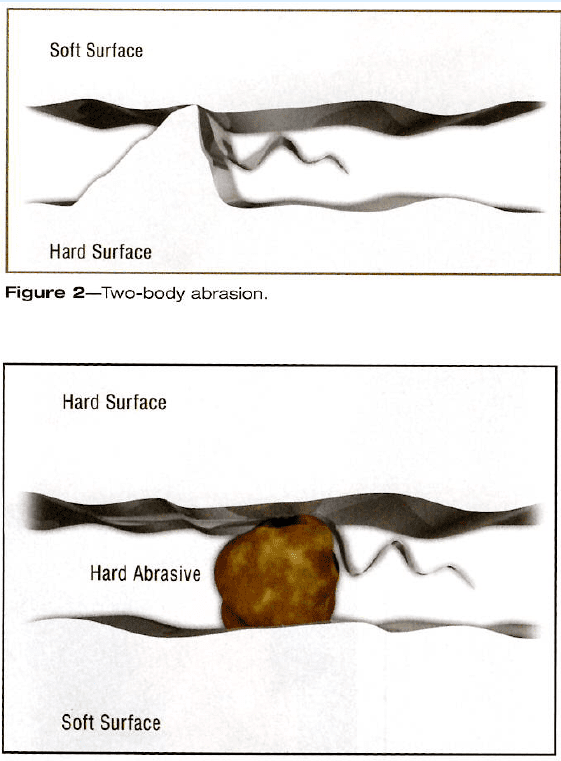

What is the No. 1 Cause and the No. 1 Consequence of Wear?

Particles. Think about it. Tribological studies on wear-related machine failure rank particle-induced abrasion as the No. 1 cause of wear. Read More