-

Blotter Spot Testing for Metallic and Other Solid Particles

The blotter spot test has been discussed numerous times in the pages of Machinery Lubrication magazine. It not only is one of the oldest oil analysis tests (mid-19th century) but endures as one of the most effective at detecting and even quantifying certain lubricant abnormalities. Read More

-

Sampling Methods for Used Oil Analysis

Sampling is arguably the most important step in the oil analysis process. If the sample in the bottle fails to effectively represent the lubricant and the condition of the machine from which it was drawn, no meaningful conclusions can be from the oil analysis data. Read More

-

Elements of a Successful Oil Analysis Program – Part I & II

Most often, users associate an oil analysis program with a systematic early alert to oil or machine failure, i.e., damage control. While these benefits are helpful and frequently achieved, they should be regarded as low on the scale of importance compared to the more rewarding objective of failure avoidance. Read More

-

Lubricant-Based Techniques for the Condition Monitoring of Non-Circulating Gear and Bearing Systems

The best maintenance techniques for mechanical machinery are condition-based techniques. Condition-based maintenance is maintenance prescribed by the real-time needs of the machine according to changes in specific operation conditions. These conditions fall into two categories. Read More

-

The Anatomy of a Filter Inspection Report

When the history of the condition monitoring field is written, there will likely be a chapter, or at least a few pages, on the odd paradox surrounding how infrequently use of used filter testing was employed (in the beginning). Read More

-

The Ten Most Common Reasons Why Oil Analysis Programs Fail & the Strategies That Effectively Overcome Them (booklet)

Many have read the well-documented case studies that convincingly demonstrate the practice of used oil analysis as a sound approach to reduce maintenance and downtime costs. However, for most users, these rewards have evaded their best efforts due to common implementation errors. Like many pursuits in life, there is often a very fine line that… Read More

-

In Search of a Definition – What is Oil Analysis?

The term “oil analysis” has been used with respect to lubrication and machine reliability since the 19th century. Yet, over the years I have seen only a few attempts to assign a specific definition to the activity despite its widespread application in industry. Most of these definitions are too narrow or fail to include important… Read More

-

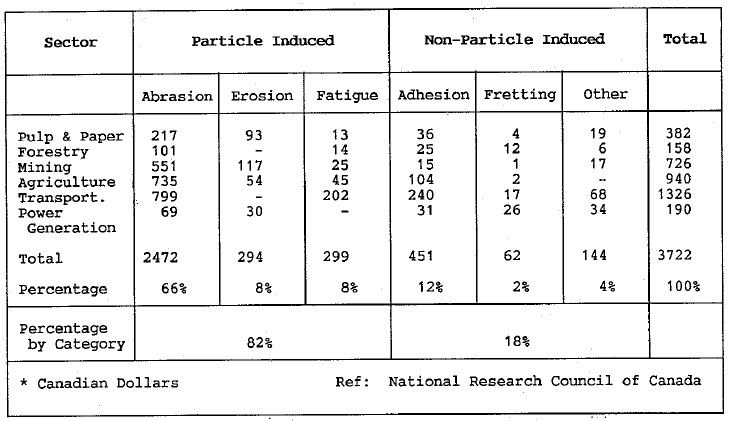

What is the No. 1 Cause and the No. 1 Consequence of Wear?

Particles. Think about it. Tribological studies on wear-related machine failure rank particle-induced abrasion as the No. 1 cause of wear. Read More

-

Oil Analysis Effectively Uncovers Hidden Problems

Oil analysis is about surfacing problems that were otherwise hidden from view. We’ve all heard the phrase “if it ain’t broke don’t fix it,” but an important corollary is “if it is broke, fix it fast.” The basic problem with this strategy is not knowing when something is actually broken. Read More