Category: Contamination Control

Jim Fitch authored articles & papers

-

Contamination Control Strategies for Planned Oil Cleanliness

Despite the good intentions of many organizations, real improvements in contamination control often remain an elusive concept. They know that invisible particles are one of the largest single contributors to progressive wear of machinery. Read More

-

Moisture – The Second Most Destructive Lubricant Contaminant

With few exceptions, the chemical and physical stability of lubricants are threatened by even the slightest amount of suspended water. Read More

-

Proactive Maintenance Can Yield More Than a IO-Fold Savings Over Conventional Predictive/Preventive Maintenance Programs

Plainly stated, the burgeoning cost of maintenance is a serious business problem. According to DuPont, “maintenance is the largest single controllable expenditure in a plant: in many companies it often exceeds annual net profit.” Read More

-

Control and Management of Particle Contamination in Hydraulic Fluids

It has been extensively documented and widely stated that particle contamination is the number one cause of wear and failure of hydraulic components. The problem is generally more pronounced than in other types of machinery incorporating circulating systems that use sirnjlar types of oils. Read More

-

Glycol In Lubricating Oil – Detection, Analysis and Removal

Introducing glycol into lubricating oils exposes your machines to a powerful and poisonous mixture of chemicals. Unlike other harmful contaminants such as water and dirt, the destructive potential of glycol can progress to massive failure of machine components in a narrow window of time. Read More

-

Justifying the Cost of Excluding a Gram of Dirt [the economics of controlling contaminant ingression)

For years Noria has been saying, “The cost of excluding a gram of dirt is probably only about 10 percent of what it will cost you once it gets into your oil.” Recently, a Noria training client asked us to document proof of this statement. Read More

-

Proactive Maintenance – The New Technology for Cost-Efficient Contamination Controlof Mechanical Machinery

It has been proven that almost all mechanical failures are caused by contamination; hard particle contamination to be ·specific. Once the root cause of machine failure has been defined, a program to correct these failures, extend machine life, and reduce maintenance costs must be developed. Such a program has been developed; it is called Proactive… Read More

-

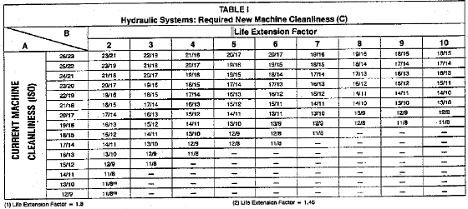

Quantifying The Contaminant Tolerance of Hydraulic Systems Using the Contaminant Life Index

Users of hydraulic equipment need to know how clean their fluid should be. The information and procedure for determining this has not been readily available in the past. Read More

-

Strategic Implementation and Cost/Benefit of Contamination Control

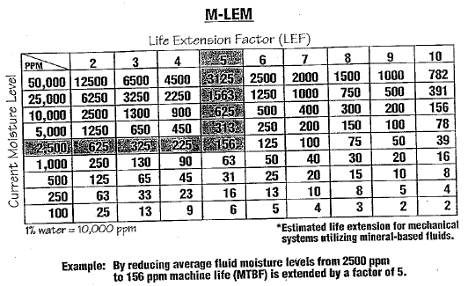

Contamination control encompasses the subject of machine life and maintenance costs. This paper discusses the Life Extension Method (LEM), a program to extend the meantime between failures based on improved fluid cleanliness levels. Read More

-

Deploying the Invisible Filter

To some contamination control might seem a little like an old tune. After all, hasn’t filtration been around nearly as long as lubrication? And, what’s new that hasn’t already been thoroughly explored and widely applied? Read More

-

Establishing and Maintaining Levels of Cleanliness [in Lubricants]

Process plants and manufacturing companies have machinery lubricated by mineral-based or synthetic fluids and other machinery powered by lower viscosity hydraulic fluids. Read More

-

Headspace Management – Are You in On This Best-Kept Contamination Control Secret?

By now, most lubrication professionals are keenly aware of the reliability gains associated with contamination control. Those who have traveled down this road know that clean and dry lubricants often come at a price. Read More

-

Dust Cakes: What Causes Them and Why You Should Care

We’ve all seen them. Perhaps some of us daily. Many take on a certain beauty, almost like a natural cave formation or a work of art. Most have organic characteristics like mosses or algae. Read More

-

How Filters Work to Control Contamination in Oil

Imagine the filter inside your machine is made of fibers the size of telephone poles, stacked randomly in all directions, many layers thick. Each juncture where poles touch is a drop of super glue for support. To emulate actual operating conditions, the stack of poles is placed on a large moving and vibrating table. Read More

-

Reliability’s Dirty Little Secret

This was one of those defining moments. It was some surprising insight on where maintenance and reliability professionals are in the journey to lubrication excellence. Read More

-

The Power of 10X Cleaner…Dryer…Cooler…Better Aligned…More Training

Have you ever considered how we might be rewarded if we improved something by 10 times? For instance, what if we were 10 times richer; would we be 10 times happier? How about if we were 10 times smarter; would we be 10 times more successful? What if we worked 10 times harder? How might… Read More

-

No Contamination, No Wear, No Kidding

I realize that this statement – No Contamination, No Wear, No Kidding – may not sit well with some readers, such as a few purists within the tribology community. But before anyone gets too excited, let me start by listing my assumptions: Read More