Category: Proactive Maintenance

Jim Fitch authored articles & papers

-

Why Proactive Maintenance is Key for a World-Class Lubrication Program

It is no surprise that those who enter the maintenance field are mechanics at heart. These are people who possess a native love for machinery and the thrill that comes from making broken things run again. Read More

-

Proactive Maintenance is a Blueprint for Success

It can take just one breakdown of a critical machine to spin an entire plant into an immediate production halt. At this point, it is too late for the plant manager to do anything but call a service technician, then gasp for air while counting the lost production. Read More

-

Proactive Maintenance is the Cost Reduction Strategy for Diesel Engines and Gas Turbines

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating lives many times that attainable just a few years ago. Read More

-

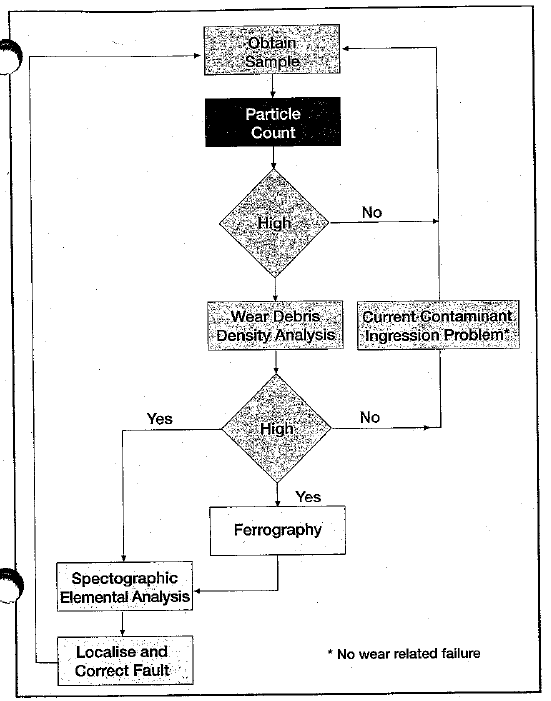

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. Read More

-

Proactive Maintenance Cleans Up on Predictive/Preventive Methods

According to major industries throughout the world, it’s time to throw out your old ideas on machine maintenance. The costsaving trend is toward a maintenance program that targets the root causes of machine wear and failure. Predictive and preventive methods are out: pro-active maintenance is in. Read More

-

Proactive Maintenance–A Cost Reduction Strategy

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating Iives many times more attainable than just a few years ago. Read More

-

Proactive Maintenance’s Unruly Cousin

Indeed it’s hard to justify spending time and money on things that aren’t yet broken when your maintenance staff is hog-tied, fixing the things that have broken. When breakdowns occur… well, you know the drill… not much else gets done until things are up and running again. Read More

-

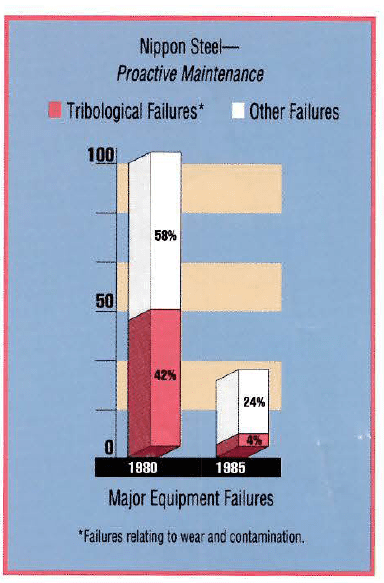

Extensive Cost Saving Opportunity from Strategic Implementation of Proactive Maintenance in the Iron and Steel Industry

Recently, maintenance managers and corporate executives have shown a greater interest in rising maintenance costs and failure rates. The realization of the need to curb these costs has logically brought about the field of proactive maintenance. This is a program that concentrates on minimizing downtime and maximizing machine life. Read More