By Jim Fitch

Machinery Lubrication Magazine

Excessive heat is a severe contaminant. It wreaks havoc on oil (chemically and physically) and retards lubricant performance by increasing wear, corrosion and friction. Friction and wear cause more heat, which sends the machine into a cycle of despair.

Heat must be controlled within the machine’s operating limits. This varies considerably between machine types and applications. Lubricants have their own unique limits as well.

Attempting to solve heat problems by simply adding a cooler or enlarging the cooler just masks the symptom and prolongs the solution. Abnormal heat is a telegraphed S.O.S. call that commands attention and remediation.

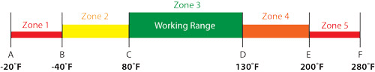

Critical temperatures on most high-speed and high-value machines are monitored in real time, often at multiple points, such as guide and thrust bearings (typically imbedded thermal couples). A common example of bearing temperature monitoring is shown in Figure 1.

Here, a temperature excursion was noticed first before any other symptoms. After inspection, a lubrication issue (cake-lock) was found to be the root cause.