-

Proactive Maintenance Cleans Up on Predictive/Preventive Methods

According to major industries throughout the world, it’s time to throw out your old ideas on machine maintenance. The costsaving trend is toward a maintenance program that targets the root causes of machine wear and failure. Predictive and preventive methods are out: pro-active maintenance is in. Read More

-

Proactive Maintenance–A Cost Reduction Strategy

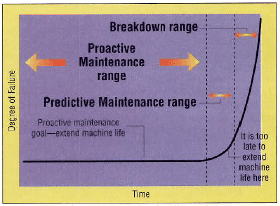

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating Iives many times more attainable than just a few years ago. Read More

-

Reliability’s Dirty Little Secret

This was one of those defining moments. It was some surprising insight on where maintenance and reliability professionals are in the journey to lubrication excellence. Read More

-

The Power of the Patch. Comparing Particle Analysis Methods

The practice of transferring suspended particles to the surface of a membrane for analysis has been around for decades. It is perhaps the earliest method for inspecting solid contaminants and wear debris in a used sample of oil. Read More

-

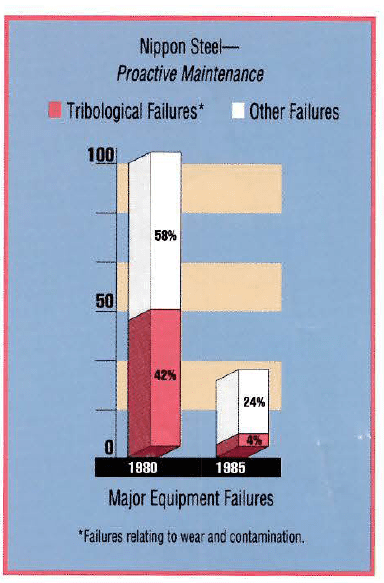

Extensive Cost Saving Opportunity from Strategic Implementation of Proactive Maintenance in the Iron and Steel Industry

Recently, maintenance managers and corporate executives have shown a greater interest in rising maintenance costs and failure rates. The realization of the need to curb these costs has logically brought about the field of proactive maintenance. This is a program that concentrates on minimizing downtime and maximizing machine life. Read More

-

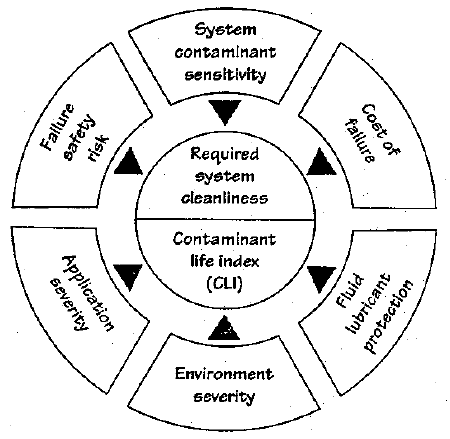

No Contamination, No Wear, No Kidding

I realize that this statement – No Contamination, No Wear, No Kidding – may not sit well with some readers, such as a few purists within the tribology community. But before anyone gets too excited, let me start by listing my assumptions: Read More

-

Precision Lubrication for the Power Generation Industry

Machinery lubrication is critical to reliability efforts at a power plant. Numerous studies cite poor or ineffective management of the lubrication process as a leading cause of forced plant outages. Read More

-

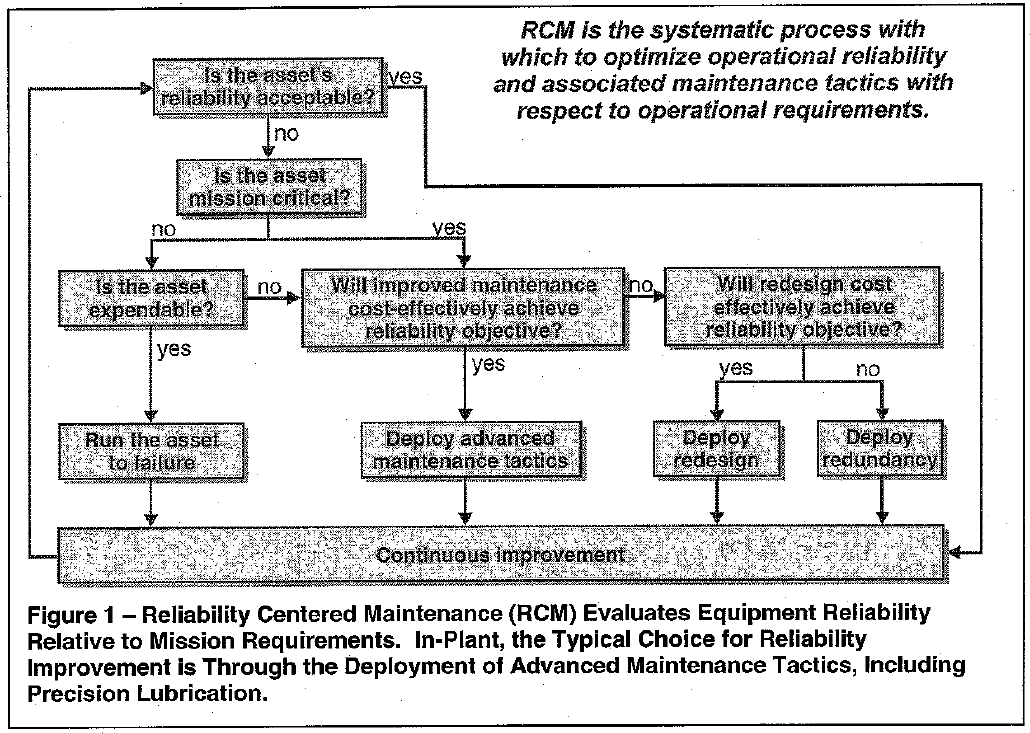

Proactive maintenance targets extending machine life

Equipment maintenance costs represent an unclaimed gold mine of savings opportunities. Yet deep maintenance cost reductions have evaded the efforts of even the most diligent and sophisticated operations. Why? Because there has been a general lack of emphasis on maintenance that corrects root causes, as opposed to responding to the symptoms or results of failure. Read More