-

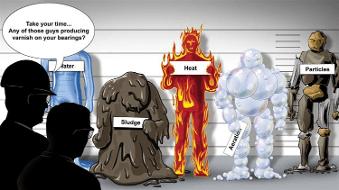

Root Cause Analysis for Lubrication Failures

Knowing when a piece of equipment is going to fail (predictive maintenance) is much more difficult than making it last long (proactive maintenance). Even more complex is root cause analysis (RCA) which is performed postmortem, like an autopsy. Read More

-

Be Proactive to Avoid Root Cause Fault Bubbles

No warning or short-warning failures are the worst kind. Think of a tire. It can wear out slowly over thousands of driving miles or rupture suddenly, at full highway speed, from a random piece of road debris. You can monitor tread loss over time and conveniently schedule a tire change. Conversely, who could predict the… Read More

-

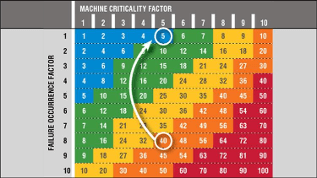

Managing Reliability in Real Time – The Risk Management Grid (RMG)

In a past article,1 I mentioned that in the world of reliability, risk can be defined as the probability of failure multiplied by the consequence(s) of failure. This simple definition should be a reliability team’s most important daily metric. In this editorial, a two-dimensional matrix is proposed that serves as a real-time moving picture of… Read More

-

A New Look at Criticality Analysis for Machinery Lubrication

For any given machine, how critical is its reliability? What if it failed suddenly and catastrophically? What would be the consequences – lost production, expensive repairs, fatality? Criticality is the logical starting point for all reliability initiatives. Read More

-

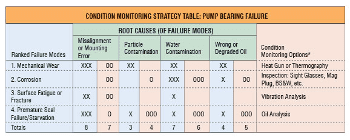

Today’s Oil Detectives Have a New Bag of Tricks

The truth is, oil analysis is detective work, plain and simple. Today’s detectives are empowered with a growing bag of tricks but frankly, only a few of these tricks involve traditional “oil analysis.” Read More