Category: Lubricant Analysis

Jim Fitch authored articles & papers

-

Blotter Spot Testing for Metallic and Other Solid Particles

The blotter spot test has been discussed numerous times in the pages of Machinery Lubrication magazine. It not only is one of the oldest oil analysis tests (mid-19th century) but endures as one of the most effective at detecting and even quantifying certain lubricant abnormalities. Read More

-

Elements of an Oil Analysis Program

Whenever a proactive maintenance strategy is applied, three steps are necessary to insure that its benefits are achieved. Since proactive maintenance, by definition, involves continuous monitoring and controlling of machine failure root causes, the first step is simply to set a target. or standard, associated with each root cause. Read More

-

Fundamentals Of Fluid Analysis for Industrial Machinery

Every industrial organization has experienced the consequences of shoddy maintenance: contract penalties, junked parts, injuries, catastrophic damage, ballooning costs, missed shipping dates, irate customers, and sickly quarterly financial reports. Today, machinery and equipment can be maintained to achieve useful operating lives many times those attainable just a few years ago. For oil lubricated machinery, the… Read More

-

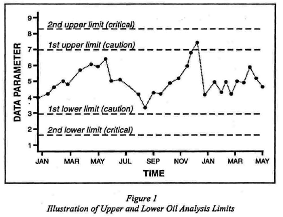

Proactive and Predictive Strategies for Setting Oil Analysis Alarms and Limits

Abstract: In oil analysis, well placed alarms and limits are like trip wires, alerting operators and technicians to an untoward or threatening condition. Oil analysis limits can vary considerably according to machine type, oil type, and reliability goals. This paper discusses four distinct types of limits and how they are applied to different machine and… Read More

-

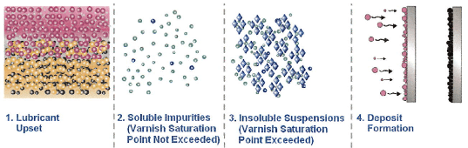

Review of Degradation Mechanisms Leading to Sludge and Varnish in Modem Turbine Oil Formulations

A wide range of fluid degradation and contamination-related issues can affect turbine lube oil systems. One serious and growing concern is the presence of sludge and varnish. Read More

-

Should New Lubricant Deliveries be Tested?

They are labeled and stored by humans. When it comes to humans, there is one inalterable constant – we make mistakes. Sometimes this is due to lack of vigilance. Sometimes it’s lack of knowledge. It might even be because of indifference. Read More

-

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

Analysis of In-Service Automotive Engine Oils

Most oil analysis performed in North America is done on diesel engine crankcase oils, primarily for large fleets in the transportation and off-road equipment industries. Ranking second would be the analysis of lubricants used in stationary industrial machinery including compressors, turbines, gearing, bearing lubes, and hydraulics. Far down the list is engine oil analysis performed… Read More

-

Elements of a Successful Oil Analysis Program – Part I & II

Most often, users associate an oil analysis program with a systematic early alert to oil or machine failure, i.e., damage control. While these benefits are helpful and frequently achieved, they should be regarded as low on the scale of importance compared to the more rewarding objective of failure avoidance. Read More

-

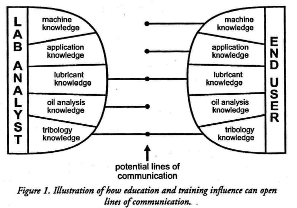

How to Develop a “Win-Win” Relationship With Your Oil Analysis Lab

Turning an oil analysis program into a feisty profit center is well within reach of today’s modern maintenance organizations. In fact, it is commonly achieved. Read More

-

How to Make Your Oil Analysis Program Produce More Alerts

I want bad news fast. Why? Problems tend to compound. Rarely do they heal themselves. Instead, the worse things get, the faster they get worse. As time passes, the cost of repair and lost production can soar exponentially. Read More

-

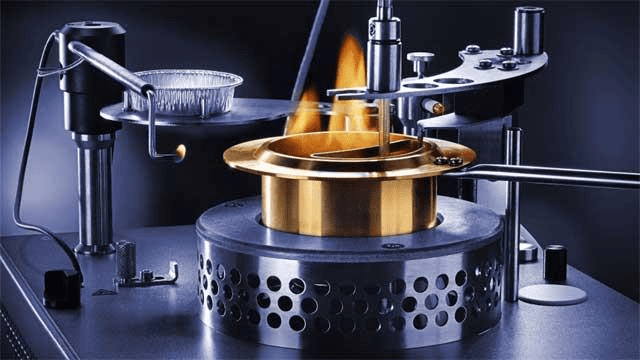

How to Test Flash Point

Like viscosity, the flash point test has always been a standard part of a lubricant’s specification. And, because of its low cost, simplicity and versatility, the test is popular among the used oil analysis community as well. Most commonly used as a quick pass/fail test for fuel dilution, more applications have surfaced in recent years.… Read More

-

Recognizing the Symptoms of Lubricant Incompatibility

Rule No. 1: Don’t mix incompatible lubricants. Rule No. 2: When in doubt, assume that two lubricants, when mixed, will be incompatible and will exhibit adverse side effects. Read More

-

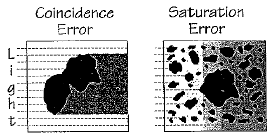

The Accuracy and Reliability of Optical Particle Counters with Industrial Oils and Hydraulic Fluids

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

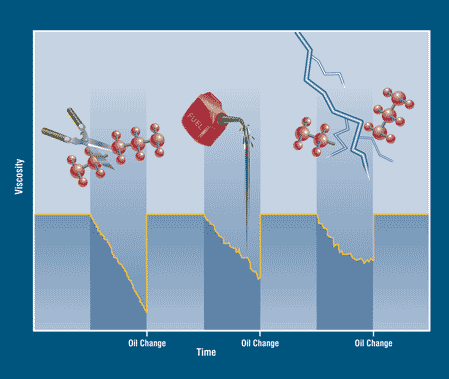

The Meaning of Low Viscosity

Viscosity can go up, down or remain unchanged. The list of root causes that can alter a viscosity reading is quite extensive; hence the reason why viscosity has become such an information-rich measure of used oil condition. After all, when viscosity has not changed, you can rightly conclude that the many known viscosity-altering factors are… Read More

-

The Power of the Patch (Comparing particle analysis methods using membranes)

The practice of transferring suspended particles to the surface of a membrane for analysis has been around for decades. It is perhaps the earliest method for inspecting solid contaminants and wear debris in a used sample of oil. It is of no surprise that these methods have enduring use today. In fact, some are the… Read More

-

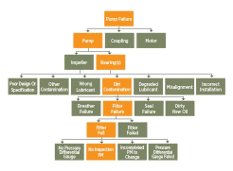

The Ten Most Common Reasons Why Oil Analysis Programs Fail & the Strategies That Effectively Overcome Them (booklet)

Many have read the well-documented case studies that convincingly demonstrate the practice of used oil analysis as a sound approach to reduce maintenance and downtime costs. However, for most users, these rewards have evaded their best efforts due to common implementation errors. Like many pursuits in life, there is often a very fine line that… Read More

-

The Wrath of Unscheduled Downtime: Why Oil Analysis is a Wise and Effective Defense

There are 8,760 hours in a year. Few plants manage to produce at full capacity for all of those hours. Instead, there are periodic production stoppages due to tooling changes, product changes, scheduled PMs/inspections and unscheduled downtime (reliability issues). Every hour the plant’s assets aren’t utilized is an hour of lost revenue and profits. Read More

-

Trouble-Shooting Viscosity Excursions

When an oil’s viscosity makes a significant change it is meaningful. The majority of the characteristics associated with wrong, contaminated or degraded lubricants will cause a change in viscosity. Restated, when trending the viscosity of a used oil and no reportable change occurs, one can conclude that many of the things that could be happening… Read More