-

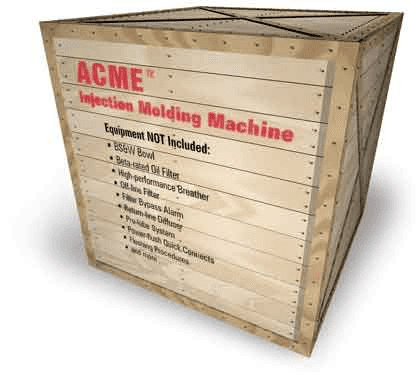

Ask Your OEM to Accessorize New Equipment for Lubrication Excellence

Has it ever occurred to you that it was necessary to specifically ask your OEM to add modern lubrication to the bill-of-material when you purchase equipment from him? Read More

-

Demand Reliability Readiness from Equipment Builders

When it comes to modern concepts in the field of lubrication and applied tribology, many users these days are far more sophisticated than those who are designing and building the machines they operate. Read More

-

Hydraulic Fluid Analysis: Avoiding the Potential Pitfalls

Analysis of hydraulic fluids, if done properly, can suggest maintenance procedures to improve hydraulic equipment reliability and extend system life. Significant cost savings can result. Read More

-

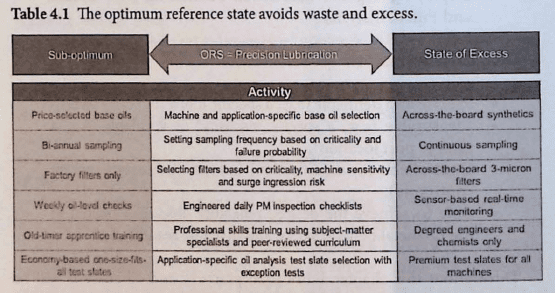

Linking Enhanced Reliability to the State of Lubrication

The lubricant Optimum Reference State (ORS) is a critical concept in the journey to world-class lubrication and enhanced machine reliability. In short, it is the prescribed state of machine configuration, operating conditions and maintenance activities required to achieve and sustain specific reliability objectives. Read More

-

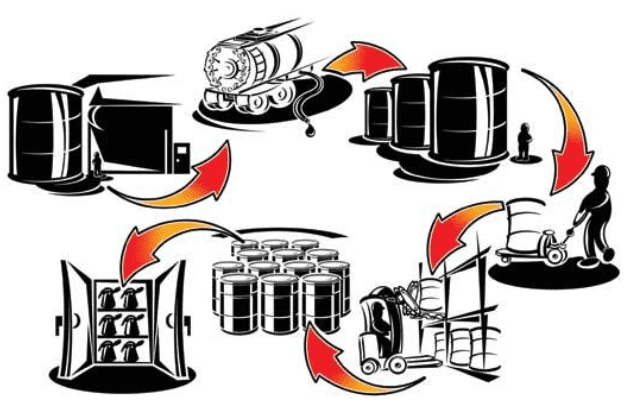

Lubricant Quality – How Does the Chain of Custody Affect It?

Lubricant users are increasingly inquiring about the cleanliness and lubricant quality of new oil deliveries. This trend is logical and probably unending as the maintenance field becomes more aware of the linkage between contamination and machine reliability. Yet there has been legitimate concerns raised by some lubricant suppliers regarding this trend. Read More

-

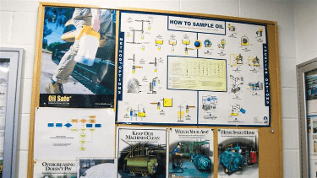

Make the Lube Room Your Lubrication Command Center

For any plant seeking lubrication excellence, there needs to be a visual starting point that sets the stage for what’s to come elsewhere in the facility. There is no better place for that than the lube room. In fact, I’ve never heard of a plant exhibiting excellence in machinery lubrication that doesn’t also exude excellence… Read More

-

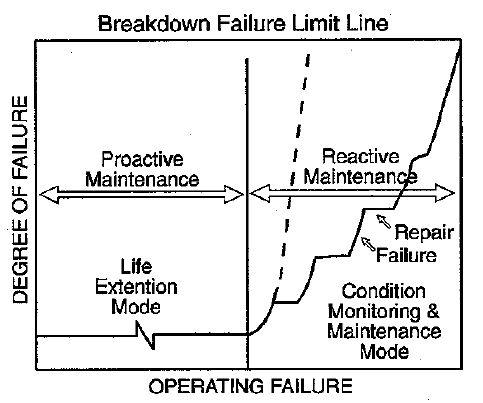

Proactive Maintenance Can Yield More Than a IO-Fold Savings Over Conventional Predictive/Preventive Maintenance Programs

Plainly stated, the burgeoning cost of maintenance is a serious business problem. According to DuPont, “maintenance is the largest single controllable expenditure in a plant: in many companies it often exceeds annual net profit.” Read More

-

The Five Cardinal Signs of a Healthy Machine

You cannot monitor your way to a healthy machine just like frequent tests for cholesterol and blood pressure do not make their readings lower. Or do they? Monitoring physical conditions brings vision and awareness to health. It is continuous feedback about how we’re doing. In a similar manner, from measured readings we can report and… Read More

-

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

Applying Satellite Communications Technology to Condition-Based Maintenance for Mobile Equipment

The advent of unattended sensor technologies has placed a particular challenge on data communication for machine surveillance monitoring. This challenge is magnified when mobile equipment and large geographic territories are involved. Read More

-

Ban the Can: Sealable, Reusable Oil Containers Are Smarter Option

The oil can was in need of a major redo years ago. It was grossly outdated in terms of modern views and needs relating to lubrication and machinery reliability. Read More

-

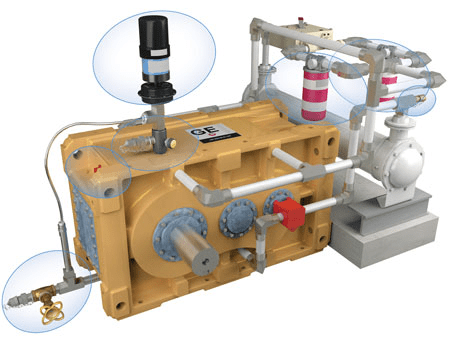

Control and Management of Particle Contamination in Hydraulic Fluids

It has been extensively documented and widely stated that particle contamination is the number one cause of wear and failure of hydraulic components. The problem is generally more pronounced than in other types of machinery incorporating circulating systems that use sirnjlar types of oils. Read More

-

Creating an Engineering Specification for Lubrication Excellence

These days an increasing number of companies are trying to achieve a state of lubrication called “lubrication excellence.” Others might call this “world-class” lubrication. Read More

-

Intervention is Key to Machine Life Extension

Try this simple experiment. With notepad in hand, go out into your plant and walk around a sampling of your most critical machines. These are the ones that have high probability of failure and/or the greatest consequences of failure. Read More

-

Justifying the Cost of Excluding a Gram of Dirt [the economics of controlling contaminant ingression)

For years Noria has been saying, “The cost of excluding a gram of dirt is probably only about 10 percent of what it will cost you once it gets into your oil.” Recently, a Noria training client asked us to document proof of this statement. Read More

-

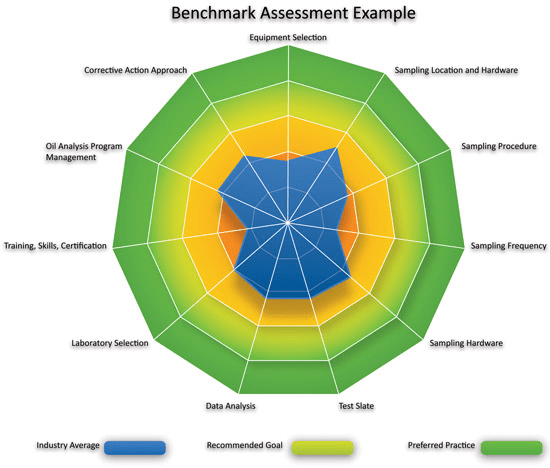

Optimizing Lubrication and Lubricant Analysis

Lubrication is an unmistakably integral part of machine reliability. Rotating machines are dependent on lubrication decisions made, such as which lubricant to use, how the lubricant needs to be applied to the tribological zones, and what is done during operations to monitor and control the integrity of these frictional zones. Read More

-

Particle Contamination — Both a Cause and a Result of Mechanical Failure

The monitoring of particle contamination in lubricating fluids is a critical indicator of incipient and impending failures. Recent research, under both laboratory and field conditions of the contaminant sensitivity of bearings, reveals a well defined cause and effect relationship between contaminant levels and relative machine life. Read More

-

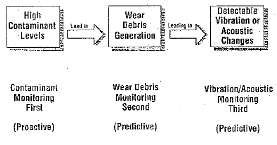

Proactive Maintenance – The New Technology for Cost-Efficient Contamination Controlof Mechanical Machinery

It has been proven that almost all mechanical failures are caused by contamination; hard particle contamination to be ·specific. Once the root cause of machine failure has been defined, a program to correct these failures, extend machine life, and reduce maintenance costs must be developed. Such a program has been developed; it is called Proactive… Read More

-

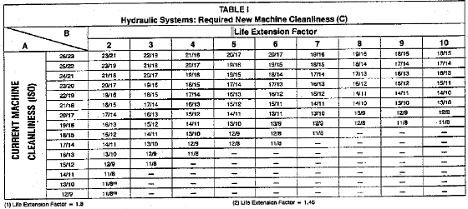

Quantifying The Contaminant Tolerance of Hydraulic Systems Using the Contaminant Life Index

Users of hydraulic equipment need to know how clean their fluid should be. The information and procedure for determining this has not been readily available in the past. Read More

-

Strategic Implementation and Cost/Benefit of Contamination Control

Contamination control encompasses the subject of machine life and maintenance costs. This paper discusses the Life Extension Method (LEM), a program to extend the meantime between failures based on improved fluid cleanliness levels. Read More