-

Elements of an Oil Analysis Program

Whenever a proactive maintenance strategy is applied, three steps are necessary to insure that its benefits are achieved. Since proactive maintenance, by definition, involves continuous monitoring and controlling of machine failure root causes, the first step is simply to set a target. or standard, associated with each root cause. Read More

-

Fundamentals Of Fluid Analysis for Industrial Machinery

Every industrial organization has experienced the consequences of shoddy maintenance: contract penalties, junked parts, injuries, catastrophic damage, ballooning costs, missed shipping dates, irate customers, and sickly quarterly financial reports. Today, machinery and equipment can be maintained to achieve useful operating lives many times those attainable just a few years ago. For oil lubricated machinery, the… Read More

-

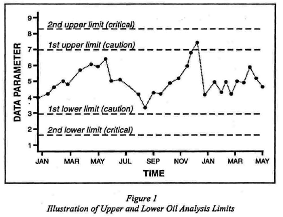

Proactive and Predictive Strategies for Setting Oil Analysis Alarms and Limits

Abstract: In oil analysis, well placed alarms and limits are like trip wires, alerting operators and technicians to an untoward or threatening condition. Oil analysis limits can vary considerably according to machine type, oil type, and reliability goals. This paper discusses four distinct types of limits and how they are applied to different machine and… Read More

-

Analysis of In-Service Automotive Engine Oils

Most oil analysis performed in North America is done on diesel engine crankcase oils, primarily for large fleets in the transportation and off-road equipment industries. Ranking second would be the analysis of lubricants used in stationary industrial machinery including compressors, turbines, gearing, bearing lubes, and hydraulics. Far down the list is engine oil analysis performed… Read More

-

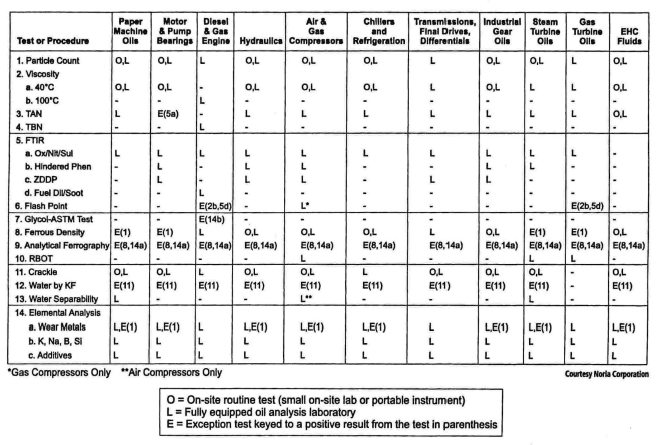

Successful Oil Analysis Practices in the Industrial Plant

Every industrial organization has experienced the consequences of shoddy maintenance: contract penalties, junked parts, injuries, catastrophic damage, ballooning costs, missed shipping dates, irate customers, and sickly quarterly financial reports. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be… Read More

-

Five Essential Lube Oil Properties Not Routinely Reported by Your Oil Lab

You may be surprised to learn that there are no less than five lubrication performance properties that are missing from nearly all in-service oil analysis reports. These are not esoteric properties that are of limited value or interest to those in charge of machine reliability. Instead, they represent the core foundation of a lubricant’s formulation… Read More