-

Contamination Control Strategies for Planned Oil Cleanliness

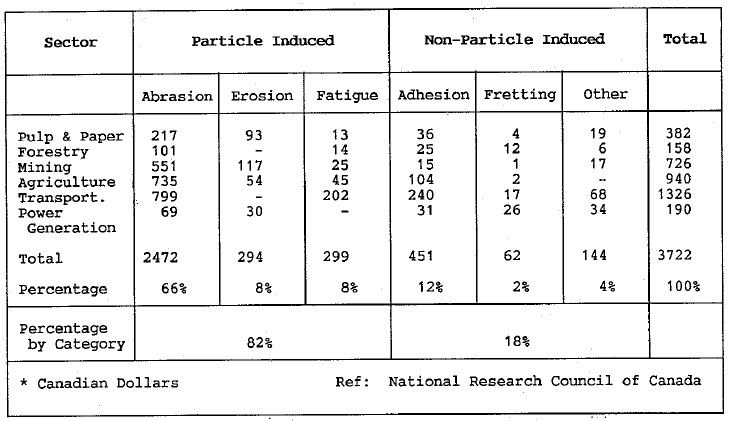

Despite the good intentions of many organizations, real improvements in contamination control often remain an elusive concept. They know that invisible particles are one of the largest single contributors to progressive wear of machinery. Read More

-

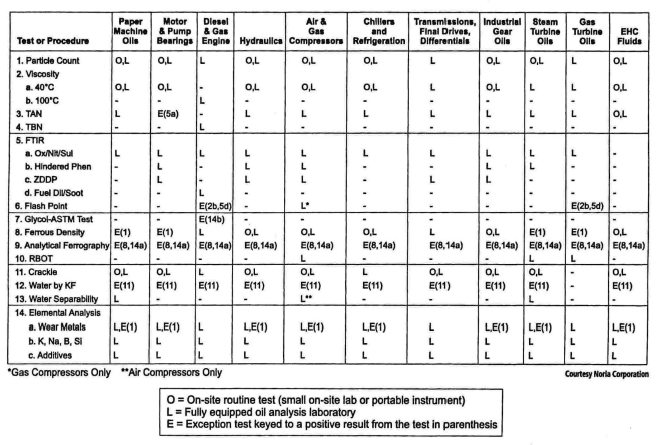

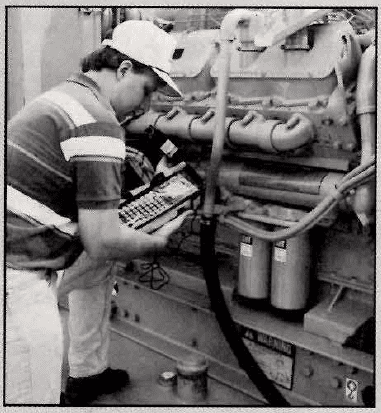

Elements of an Oil Analysis Program

Whenever a proactive maintenance strategy is applied, three steps are necessary to insure that its benefits are achieved. Since proactive maintenance, by definition, involves continuous monitoring and controlling of machine failure root causes, the first step is simply to set a target. or standard, associated with each root cause. Read More

-

Fundamentals Of Fluid Analysis for Industrial Machinery

Every industrial organization has experienced the consequences of shoddy maintenance: contract penalties, junked parts, injuries, catastrophic damage, ballooning costs, missed shipping dates, irate customers, and sickly quarterly financial reports. Today, machinery and equipment can be maintained to achieve useful operating lives many times those attainable just a few years ago. For oil lubricated machinery, the… Read More

-

Hydraulic Fluid Analysis: Avoiding the Potential Pitfalls

Analysis of hydraulic fluids, if done properly, can suggest maintenance procedures to improve hydraulic equipment reliability and extend system life. Significant cost savings can result. Read More

-

An Introduction to Fluid Contamination Analysis

Oil contamination may be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial, and may be detrimental, to the performance of the oil and/or the operating machinery. Read More

-

Analysis of In-Service Automotive Engine Oils

Most oil analysis performed in North America is done on diesel engine crankcase oils, primarily for large fleets in the transportation and off-road equipment industries. Ranking second would be the analysis of lubricants used in stationary industrial machinery including compressors, turbines, gearing, bearing lubes, and hydraulics. Far down the list is engine oil analysis performed… Read More

-

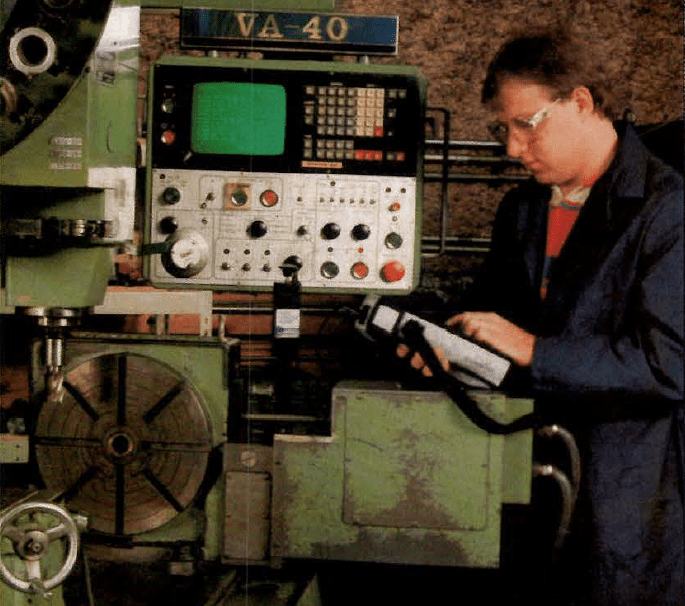

Lubricant-Based Techniques for the Condition Monitoring of Non-Circulating Gear and Bearing Systems

The best maintenance techniques for mechanical machinery are condition-based techniques. Condition-based maintenance is maintenance prescribed by the real-time needs of the machine according to changes in specific operation conditions. These conditions fall into two categories. Read More

-

Successful Oil Analysis Practices in the Industrial Plant

Every industrial organization has experienced the consequences of shoddy maintenance: contract penalties, junked parts, injuries, catastrophic damage, ballooning costs, missed shipping dates, irate customers, and sickly quarterly financial reports. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be… Read More

-

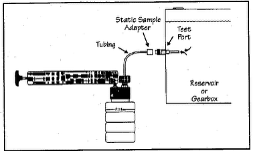

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. This has led to the discovery of a host of new tactics and practices that involve combining the particle counter with other important onsite oil analysis tools and methods. Read More

-

Comparison of Particle Counts Between Eight Commercial Oil Analysis Laboratories

The inclusion of particle counting in the periodic analysis of hydraulic and lubricating fluids has provided an important new advancement to machine diagnostics. With particle counting, machinery users can monitor the principal cause of failure, not just the symptoms, or results, of failure. The benefit, when particle levels are controlled, is extended machine life and… Read More

-

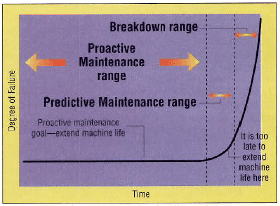

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions. Read More

-

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions: Read More

-

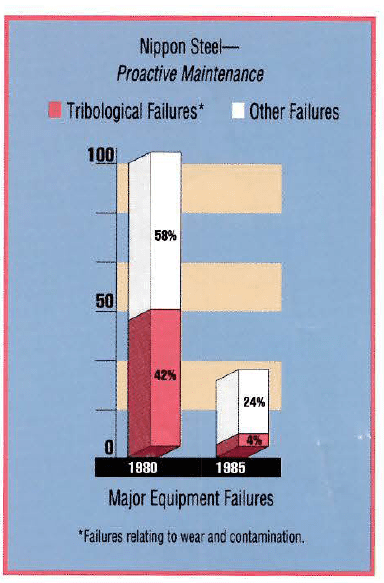

Proactive Maintenance is a Blueprint for Success

It can take just one breakdown of a critical machine to spin an entire plant into an immediate production halt. At this point, it is too late for the plant manager to do anything but call a service technician, then gasp for air while counting the lost production. Read More

-

Proactive Maintenance Cleans Up on Predictive/Preventive Methods

According to major industries throughout the world, it’s time to throw out your old ideas on machine maintenance. The costsaving trend is toward a maintenance program that targets the root causes of machine wear and failure. Predictive and preventive methods are out: pro-active maintenance is in. Read More

-

Proactive Maintenance–A Cost Reduction Strategy

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating Iives many times more attainable than just a few years ago. Read More

-

The Power of the Patch. Comparing Particle Analysis Methods

The practice of transferring suspended particles to the surface of a membrane for analysis has been around for decades. It is perhaps the earliest method for inspecting solid contaminants and wear debris in a used sample of oil. Read More

-

Proactive maintenance targets extending machine life

Equipment maintenance costs represent an unclaimed gold mine of savings opportunities. Yet deep maintenance cost reductions have evaded the efforts of even the most diligent and sophisticated operations. Why? Because there has been a general lack of emphasis on maintenance that corrects root causes, as opposed to responding to the symptoms or results of failure. Read More

-

Proactive Maintenance the Cost-Reduction Strategy

The field of maintenance technology going through a revolution of change. Gone are the t days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating lives many times that attainable just a few years ago. Read More