-

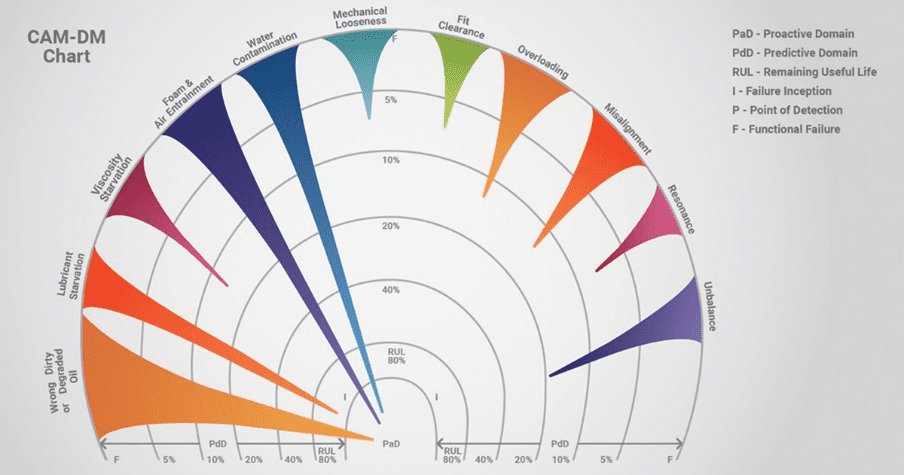

Introducing Condition Alarm Mapping (CAM)

The sheer number of infographics in the condition monitoring field is staggering; they show up on social media, and in conference presentations, whitepapers, websites and books. Infographics are effective at helping people comprehend difficult concepts that integrate an array of variables and factors. Read More

-

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

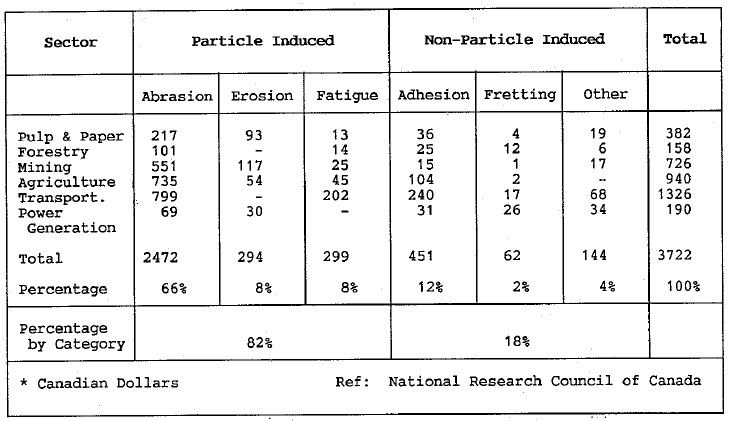

Tricks to Classifying Wear Metals and Other Used Oil Suspensions

The most common methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. For some users, because of the criticality of the application, all of these screening tests for wear metals are integrated into the routine test slate. Read More

-

Why Inspection 2.0 Is Your Best Strategy for Early Fault Detection

Inspection, in its most basic form, has been around forever. However, like most things in life, what you get out of an activity depends entirely on what you put in. This column is about radical reinvention of the whole concept of machine inspection. It has little to do with conventional practices of doing daily machine… Read More

-

Be Proactive to Avoid Root Cause Fault Bubbles

No warning or short-warning failures are the worst kind. Think of a tire. It can wear out slowly over thousands of driving miles or rupture suddenly, at full highway speed, from a random piece of road debris. You can monitor tread loss over time and conveniently schedule a tire change. Conversely, who could predict the… Read More

-

Evolution of Maintenance Man

In the world of maintenance, there are two kinds of companies – those who are modernizing their maintenance programs and those who will. Companies on the trailing edge face one of two risks depending on their industry and geography: Read More

-

Getting Machines to the Proper State of Inspection Readiness

I have written several articles on inspection recently, as I strongly believe it is foundational to condition monitoring, machine reliability and asset management. My last Machinery Lubrication column introduced the term “Inspection 2.0” to differentiate conventional inspection practices from the intense, probing and purposeful methods needed to optimize benefits. As common as inspection activities may… Read More

-

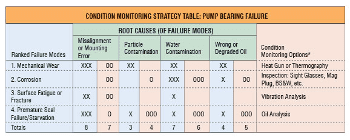

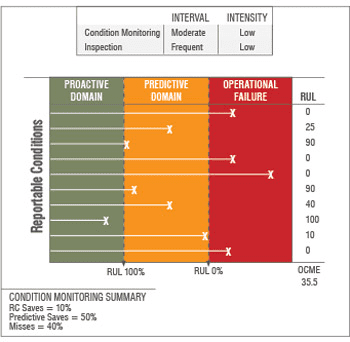

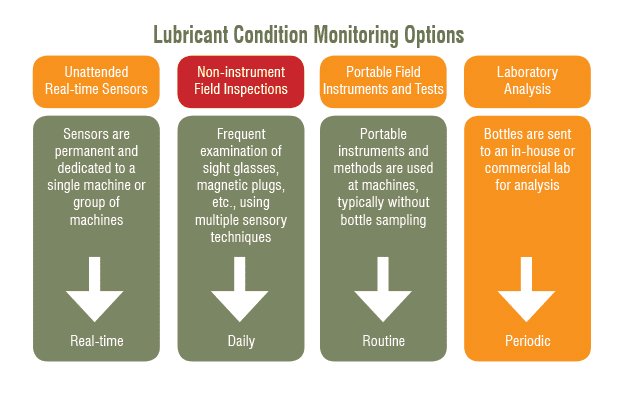

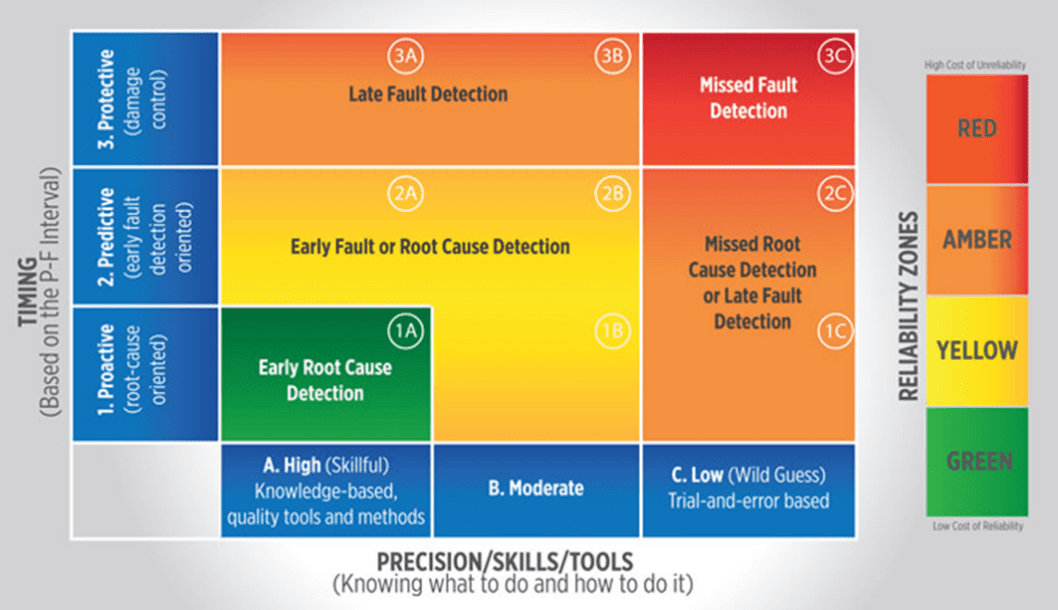

How to Measure the Effectiveness of Condition Monitoring

Condition monitoring should never be limited to a single technology or method. Instead, it should combine and integrate an optimum selection of purposeful tools and tasks. Condition monitoring can be largely technology based but can also be observation or inspection based. Read More

-

How to Visually Inspect the Health and State of Oil

The well-known KISS principle (keep it simple stupid) was first coined in the 1960s and began widespread use in the U.S. Navy shortly thereafter. While it started as a design principle for engineers, it has since been applied to any activity or creative endeavor that has had the propensity to become unnecessarily complicated. Read More

-

Lubricant-Based Techniques for the Condition Monitoring of Non-Circulating Gear and Bearing Systems

The best maintenance techniques for mechanical machinery are condition-based techniques. Condition-based maintenance is maintenance prescribed by the real-time needs of the machine according to changes in specific operation conditions. These conditions fall into two categories. Read More

-

Model of a Fuzzy Logic Expert System for Real-Time Condition Control of a Hydraulic System

Condition control is defined as the interactive processes of condition monitoring, condition analysis, and condition response. A model is presented which employs the use of expert systems to achieve real-time condition control of a hydraulic system. Read More

-

Detection Zone Coding for More Efficient Condition Monitoring

These days, reliability professionals are faced with diverse options related to technologies and methods to detect, troubleshoot and remediate problems. Figure 1 is a simple example of the available options to collect data and arrive at decisions regarding the health of machinery and machine components. Read More

-

Inspection 2.0: The Cornerstone of World-Class TPM

Inspection 2.0 is rooted in some of the most fundamental and time-honored maintenance principles. One of them is total productive maintenance (TPM). Today, it’s hard to play an active role in the field of maintenance and reliability without encountering and embracing TPM. Honestly, it is delusional to think otherwise. Read More

-

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

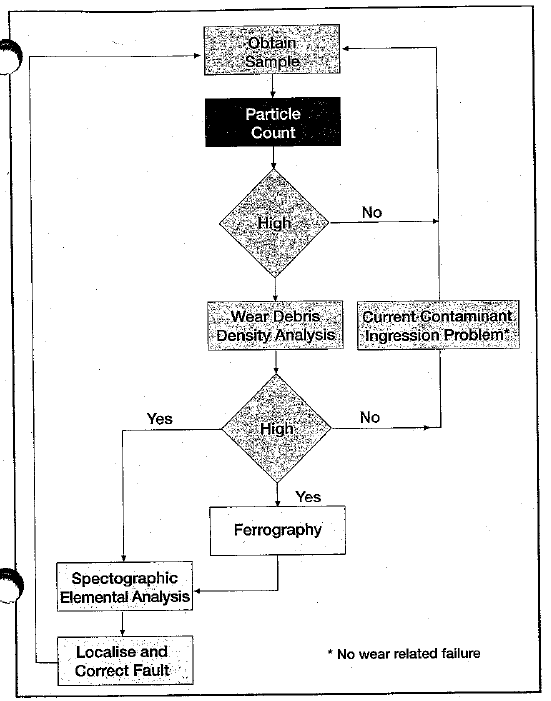

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions. Read More

-

Measure by Measure [oil analysis in machine condition monitoring]

By some estimates, condition monitoring has been around for more than a century, but it is only within the last 5-10 years (and particularly the last 2 or 3) that interest has been at fever pitch. Read More

-

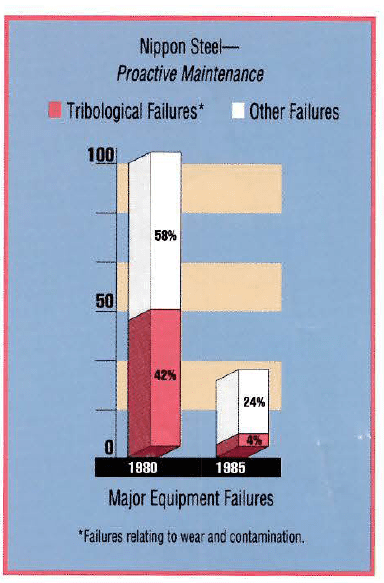

Proactive Maintenance is a Blueprint for Success

It can take just one breakdown of a critical machine to spin an entire plant into an immediate production halt. At this point, it is too late for the plant manager to do anything but call a service technician, then gasp for air while counting the lost production. Read More

-

Proactive Maintenance is the Cost Reduction Strategy for Diesel Engines and Gas Turbines

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating lives many times that attainable just a few years ago. Read More

-

The 5 States of Machine Inspection 2.0

When most of us refer to inspection, we are thinking of running machines inspected routinely, say on daily rounds. Unarguably, this type of on-the-run inspection is critical to machine condition monitoring, but other types of inspections are important as well. Read More

-

Oil Analysis Effectively Uncovers Hidden Problems

Oil analysis is about surfacing problems that were otherwise hidden from view. We’ve all heard the phrase “if it ain’t broke don’t fix it,” but an important corollary is “if it is broke, fix it fast.” The basic problem with this strategy is not knowing when something is actually broken. Read More

-

Proactive Maintenance Cleans Up on Predictive/Preventive Methods

According to major industries throughout the world, it’s time to throw out your old ideas on machine maintenance. The costsaving trend is toward a maintenance program that targets the root causes of machine wear and failure. Predictive and preventive methods are out: pro-active maintenance is in. Read More