-

Proactive Maintenance Can Yield More Than a IO-Fold Savings Over Conventional Predictive/Preventive Maintenance Programs

Plainly stated, the burgeoning cost of maintenance is a serious business problem. According to DuPont, “maintenance is the largest single controllable expenditure in a plant: in many companies it often exceeds annual net profit.” Read More

-

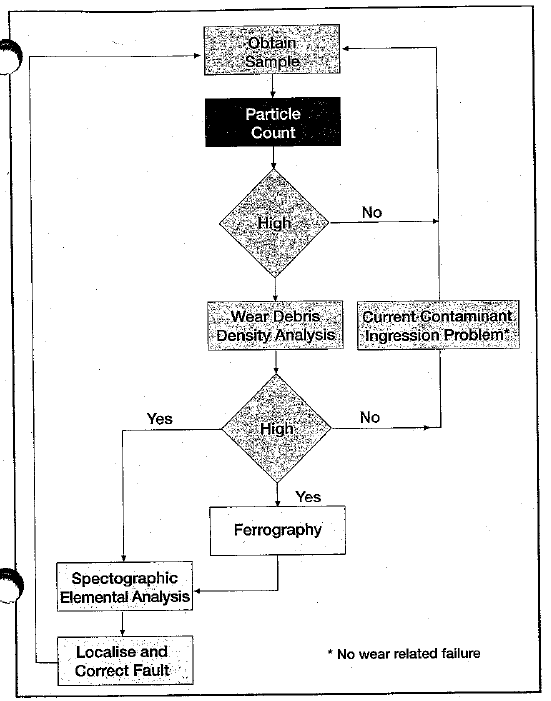

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

Why Inspection 2.0 Is Your Best Strategy for Early Fault Detection

Inspection, in its most basic form, has been around forever. However, like most things in life, what you get out of an activity depends entirely on what you put in. This column is about radical reinvention of the whole concept of machine inspection. It has little to do with conventional practices of doing daily machine… Read More

-

Be Proactive to Avoid Root Cause Fault Bubbles

No warning or short-warning failures are the worst kind. Think of a tire. It can wear out slowly over thousands of driving miles or rupture suddenly, at full highway speed, from a random piece of road debris. You can monitor tread loss over time and conveniently schedule a tire change. Conversely, who could predict the… Read More

-

Control and Management of Particle Contamination in Hydraulic Fluids

It has been extensively documented and widely stated that particle contamination is the number one cause of wear and failure of hydraulic components. The problem is generally more pronounced than in other types of machinery incorporating circulating systems that use sirnjlar types of oils. Read More

-

Evolution of Maintenance Man

In the world of maintenance, there are two kinds of companies – those who are modernizing their maintenance programs and those who will. Companies on the trailing edge face one of two risks depending on their industry and geography: Read More

-

Getting Machines to the Proper State of Inspection Readiness

I have written several articles on inspection recently, as I strongly believe it is foundational to condition monitoring, machine reliability and asset management. My last Machinery Lubrication column introduced the term “Inspection 2.0” to differentiate conventional inspection practices from the intense, probing and purposeful methods needed to optimize benefits. As common as inspection activities may… Read More

-

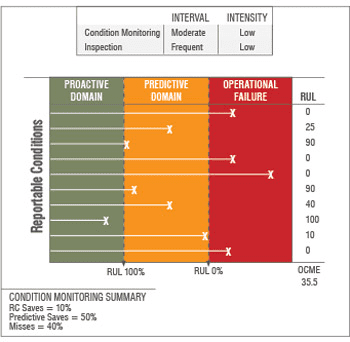

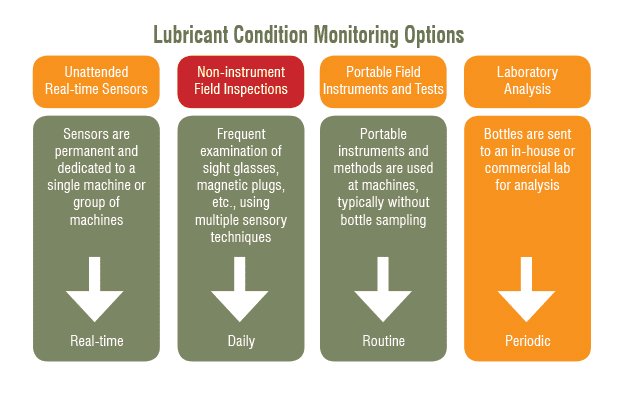

How to Measure the Effectiveness of Condition Monitoring

Condition monitoring should never be limited to a single technology or method. Instead, it should combine and integrate an optimum selection of purposeful tools and tasks. Condition monitoring can be largely technology based but can also be observation or inspection based. Read More

-

How to Visually Inspect the Health and State of Oil

The well-known KISS principle (keep it simple stupid) was first coined in the 1960s and began widespread use in the U.S. Navy shortly thereafter. While it started as a design principle for engineers, it has since been applied to any activity or creative endeavor that has had the propensity to become unnecessarily complicated. Read More

-

Model of a Fuzzy Logic Expert System for Real-Time Condition Control of a Hydraulic System

Condition control is defined as the interactive processes of condition monitoring, condition analysis, and condition response. A model is presented which employs the use of expert systems to achieve real-time condition control of a hydraulic system. Read More

-

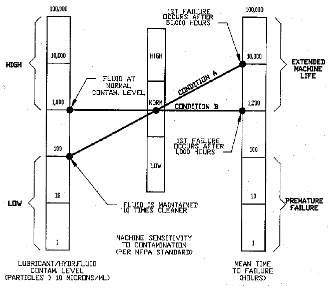

Particle Contamination — Both a Cause and a Result of Mechanical Failure

The monitoring of particle contamination in lubricating fluids is a critical indicator of incipient and impending failures. Recent research, under both laboratory and field conditions of the contaminant sensitivity of bearings, reveals a well defined cause and effect relationship between contaminant levels and relative machine life. Read More

-

The Wrath of Unscheduled Downtime: Why Oil Analysis is a Wise and Effective Defense

There are 8,760 hours in a year. Few plants manage to produce at full capacity for all of those hours. Instead, there are periodic production stoppages due to tooling changes, product changes, scheduled PMs/inspections and unscheduled downtime (reliability issues). Every hour the plant’s assets aren’t utilized is an hour of lost revenue and profits. Read More

-

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. This has led to the discovery of a host of new tactics and practices that involve combining the particle counter with other important onsite oil analysis tools and methods. Read More

-

A New Approach to Maintaining Industrial Equipment

Costly particulate contamination slowly degrades and jams machine components causing product defects, shorter machine life., increased production downtime and decreased energy efficiency. Read More

-

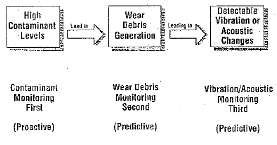

Contaminant Monitoring Targets Root Causes of Machinery Problems

A proactive maintenance approach has been particularly successful in reducing or eliminating one of the most serious equipment maintenance problems: contamination of lubricant or hydraulic fluid systems. Read More

-

Establishing and Maintaining Levels of Cleanliness [in Lubricants]

Process plants and manufacturing companies have machinery lubricated by mineral-based or synthetic fluids and other machinery powered by lower viscosity hydraulic fluids. Read More

-

Inspection 2.0: The Cornerstone of World-Class TPM

Inspection 2.0 is rooted in some of the most fundamental and time-honored maintenance principles. One of them is total productive maintenance (TPM). Today, it’s hard to play an active role in the field of maintenance and reliability without encountering and embracing TPM. Honestly, it is delusional to think otherwise. Read More

-

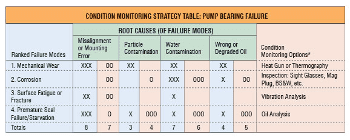

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions. Read More

-

Lubricant-Based Techniques for Condition Monitoring of Non-Circulating Gear and Bearing Systems

The majority of wear related failures occur as the direct result of particulate contamination. A recent article published in Lubrication Engineering magazine concludes that more than 82% of wear related losses are contaminant induced. Read More

-

Proactive Maintenance is the Cost Reduction Strategy for Diesel Engines and Gas Turbines

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating lives many times that attainable just a few years ago. Read More