-

The 5 States of Machine Inspection 2.0

When most of us refer to inspection, we are thinking of running machines inspected routinely, say on daily rounds. Unarguably, this type of on-the-run inspection is critical to machine condition monitoring, but other types of inspections are important as well. Read More

-

Who Should Inspect Your Lubricated Machines?

Perhaps you’ve heard that machine reliability is everyone’s responsibility. In a general sense, this is very true and needed. We should all keep our eyes alert to issues, large and small. We should foster an inspection and proactive maintenance culture. Inspection is largely about relentless and purposeful sensory observation. Any competent and responsible person near… Read More

-

Oil Analysis Effectively Uncovers Hidden Problems

Oil analysis is about surfacing problems that were otherwise hidden from view. We’ve all heard the phrase “if it ain’t broke don’t fix it,” but an important corollary is “if it is broke, fix it fast.” The basic problem with this strategy is not knowing when something is actually broken. Read More

-

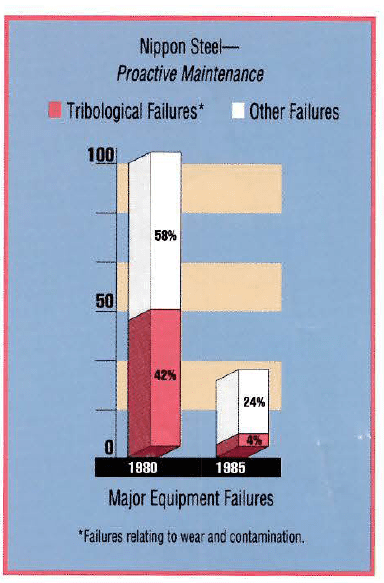

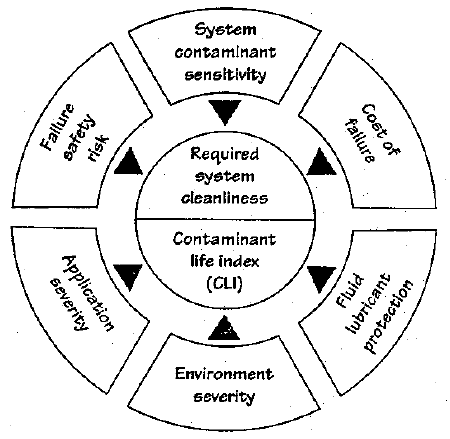

Proactive Maintenance Cleans Up on Predictive/Preventive Methods

According to major industries throughout the world, it’s time to throw out your old ideas on machine maintenance. The costsaving trend is toward a maintenance program that targets the root causes of machine wear and failure. Predictive and preventive methods are out: pro-active maintenance is in. Read More

-

Extensive Cost Saving Opportunity from Strategic Implementation of Proactive Maintenance in the Iron and Steel Industry

Recently, maintenance managers and corporate executives have shown a greater interest in rising maintenance costs and failure rates. The realization of the need to curb these costs has logically brought about the field of proactive maintenance. This is a program that concentrates on minimizing downtime and maximizing machine life. Read More

-

Is Your Oil Analysis Program a Quart Low?

Not long ago I read a magazine article on predictive maintenance that referred to oil analysis as a means to “time” an oil change. Sadly, no other application or benefit was mentioned. The author was obviously trying to give credit to the field but unknowingly diminished its importance and value. An opportunity was lost. Read More