-

Contamination Control Strategies for Planned Oil Cleanliness

Despite the good intentions of many organizations, real improvements in contamination control often remain an elusive concept. They know that invisible particles are one of the largest single contributors to progressive wear of machinery. Read More

-

Hydraulic Fluid Analysis: Avoiding the Potential Pitfalls

Analysis of hydraulic fluids, if done properly, can suggest maintenance procedures to improve hydraulic equipment reliability and extend system life. Significant cost savings can result. Read More

-

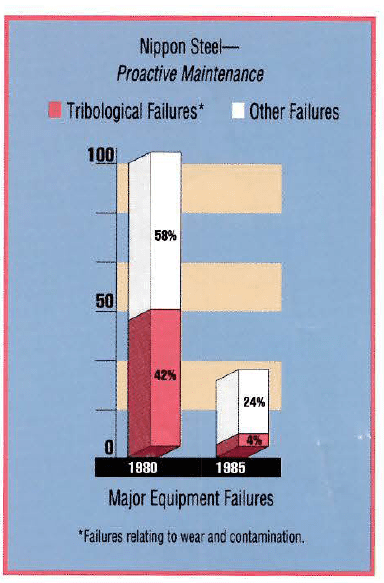

Proactive Maintenance Can Yield More Than a IO-Fold Savings Over Conventional Predictive/Preventive Maintenance Programs

Plainly stated, the burgeoning cost of maintenance is a serious business problem. According to DuPont, “maintenance is the largest single controllable expenditure in a plant: in many companies it often exceeds annual net profit.” Read More

-

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments. Read More

-

Control and Management of Particle Contamination in Hydraulic Fluids

It has been extensively documented and widely stated that particle contamination is the number one cause of wear and failure of hydraulic components. The problem is generally more pronounced than in other types of machinery incorporating circulating systems that use sirnjlar types of oils. Read More

-

Filter Flow Rate: The Silent Opportunity

In leading maintenance organizations, managers don’t shrug off the importance of cleanliness. Instead, we are seeing these companies intrepidly improve fluid cleanliness targets over and over in their quest to enhance machine reliability. However, this practice has led to new challenges relating to both the ability to achieve the new targets and the cost of… Read More

-

Justifying the Cost of Excluding a Gram of Dirt [the economics of controlling contaminant ingression)

For years Noria has been saying, “The cost of excluding a gram of dirt is probably only about 10 percent of what it will cost you once it gets into your oil.” Recently, a Noria training client asked us to document proof of this statement. Read More

-

Proactive Maintenance – The New Technology for Cost-Efficient Contamination Controlof Mechanical Machinery

It has been proven that almost all mechanical failures are caused by contamination; hard particle contamination to be ·specific. Once the root cause of machine failure has been defined, a program to correct these failures, extend machine life, and reduce maintenance costs must be developed. Such a program has been developed; it is called Proactive… Read More

-

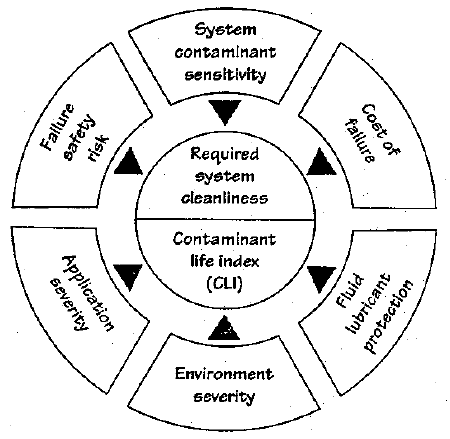

Quantifying The Contaminant Tolerance of Hydraulic Systems Using the Contaminant Life Index

Users of hydraulic equipment need to know how clean their fluid should be. The information and procedure for determining this has not been readily available in the past. Read More

-

Deploying the Invisible Filter

To some contamination control might seem a little like an old tune. After all, hasn’t filtration been around nearly as long as lubrication? And, what’s new that hasn’t already been thoroughly explored and widely applied? Read More

-

Establishing and Maintaining Levels of Cleanliness [in Lubricants]

Process plants and manufacturing companies have machinery lubricated by mineral-based or synthetic fluids and other machinery powered by lower viscosity hydraulic fluids. Read More

-

Fluid Contamination Analysis as a Maintenance Tool

Oil contamination can be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial and may even be detrimental to the performance of the oil and/or operating machinery. Read More

-

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions. Read More

-

Proactive Maintenance is a Blueprint for Success

It can take just one breakdown of a critical machine to spin an entire plant into an immediate production halt. At this point, it is too late for the plant manager to do anything but call a service technician, then gasp for air while counting the lost production. Read More

-

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. Read More

-

Increasing Demands Bring Advancements in Oil Filtration

Filtration has two primary objectives. The first objective is “protective”. This refers to creating a barrier to protect particle-sensitive machine components from the invasion of contaminants capable of causing sudden-death machine failure. Read More

-

Proactive Maintenance Cleans Up on Predictive/Preventive Methods

According to major industries throughout the world, it’s time to throw out your old ideas on machine maintenance. The costsaving trend is toward a maintenance program that targets the root causes of machine wear and failure. Predictive and preventive methods are out: pro-active maintenance is in. Read More

-

Reliability’s Dirty Little Secret

This was one of those defining moments. It was some surprising insight on where maintenance and reliability professionals are in the journey to lubrication excellence. Read More

-

Extensive Cost Saving Opportunity from Strategic Implementation of Proactive Maintenance in the Iron and Steel Industry

Recently, maintenance managers and corporate executives have shown a greater interest in rising maintenance costs and failure rates. The realization of the need to curb these costs has logically brought about the field of proactive maintenance. This is a program that concentrates on minimizing downtime and maximizing machine life. Read More

-

Particle Counting – Deploying the Invisible Filter

This past year Practicing Oil Analysis featured many end-user case studies documenting cost savings from oil analysis. Surprisingly, the majority of these studies describe the partnering of oil analysis with contamination control*. Read More