-

11 Tactics for a Strategic Oil Flushing Program

About 15 years ago, I added a new file to my library of technical literature – a folder into which I put a single magazine article on flushing procedures. Today the file is bulging with papers, articles, procedures and industrial standards on this single subject.

-

8 Pillars to a Prosperous Maintenance Culture

It ain’t just about the oil. In recent years, it has become increasingly clear to me that applied tribology is more about training and behavioral science than about engineering and material science.

-

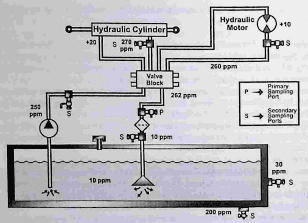

Advancements in Fluid Analysis Technologies and Strategies for Hydraulic SystemCondition-Based Maintenance

World-class condition monitoring of hydraulic systems involves the successful integration of a number of strategic elements. While in the past, walk-around inspections and gage data were the primary means of monitoring system health, today’s modem oil analysis programs apply a host of sophisticated new tools and instruments.

-

Advantages of a Unified Condition Monitoring Approach

For most plants, condition monitoring consists of multiple technologies that are cobbled together in an attempt to enhance machine reliability. Clearly, these efforts are founded in good intentions, and many such programs enjoy considerable success. Still others languish due to a lack of symmetry and central focus. Money is spent and efforts expended, but results…

-

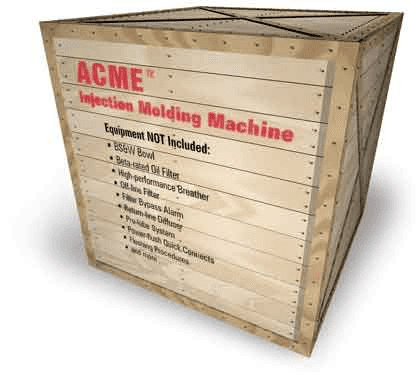

Ask Your OEM to Accessorize New Equipment for Lubrication Excellence

Has it ever occurred to you that it was necessary to specifically ask your OEM to add modern lubrication to the bill-of-material when you purchase equipment from him?

-

Avoiding the Pitfalls of Viscosity-starved Machines

Industry rides on a film of oil. The oil’s viscosity bears the load and defines the extent of clearance achieved between working surfaces. Sometimes that clearance is thick and bountiful, and other times it is deflated or extinct. Without viscosity, most machines would rapidly self-destruct with mechanical friction and wear.

-

Blotter Spot Testing for Metallic and Other Solid Particles

The blotter spot test has been discussed numerous times in the pages of Machinery Lubrication magazine. It not only is one of the oldest oil analysis tests (mid-19th century) but endures as one of the most effective at detecting and even quantifying certain lubricant abnormalities.

-

Conservation of Lubricants and Energy

Many of the materials essential to global industrial markets have been identified as being in potential short supply. A substantial number of those materials originate from regions of the world where interrupted supply is a real and present risk. Petroleum is a finite world resource with continuing supply and economic problems, with more special concerns…

-

Contamination Control Strategies for Planned Oil Cleanliness

Despite the good intentions of many organizations, real improvements in contamination control often remain an elusive concept. They know that invisible particles are one of the largest single contributors to progressive wear of machinery.

-

Deciphering Important Visual Features of Wear Particles

When working from a single sample, it is common for labs to classify wear particles according to standardized shapes such as platelets, chunks, ribbons and spheres. T

-

Demand Reliability Readiness from Equipment Builders

When it comes to modern concepts in the field of lubrication and applied tribology, many users these days are far more sophisticated than those who are designing and building the machines they operate.

-

Demystifying Sludge and Varnish

The approach of detecting and analyzing sludge and varnish problems in machinery is not the same as used oil analysis. In many instances this is because the evidence is not always in the oil.

-

Develop a Corporate Education Master Plan

Reliability and lubrication excellence are behavioral sciences. Bearings don’t just die; they’re murdered by people. What can change behavior? It requires awareness and know-how.

-

Education and User Empowerment

As oil analysis specialists, we had much to offer; and in the past 10 years, we’ve given hundreds of seminars and graduated thousands of students. However, we’ve also learned much from these students, especially details on the purpose for their hunger for knowledge in oil analysis.

-

Elements of an Oil Analysis Program

Whenever a proactive maintenance strategy is applied, three steps are necessary to insure that its benefits are achieved. Since proactive maintenance, by definition, involves continuous monitoring and controlling of machine failure root causes, the first step is simply to set a target. or standard, associated with each root cause.

-

Five Ways Aerated Oil Wrecks Machines

We’re told machines should not be allowed to swallow air. But what if they do? What harm could be caused by this bubbly stuff anyway? Do we really have to make the machine burp?

-

Five Ways to Reduce Lubricant Spending

Lubricant procurement is not the largest expenditure in a typical maintenance budget. However, it is viewed as a real, tangible expense that is frequently targeted for cost reduction. When it comes to lubricants, it is unwise to pretend to save money by “buying cheap.”