-

Inspection 2.0: The Cornerstone of World-Class TPM

Inspection 2.0 is rooted in some of the most fundamental and time-honored maintenance principles. One of them is total productive maintenance (TPM). Today, it’s hard to play an active role in the field of maintenance and reliability without encountering and embracing TPM. Honestly, it is delusional to think otherwise.

-

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions.

-

Interpreting Contaminant Analysis Trends into a Proactive and Predictive Maintenance Strategy

Condition monitoring can be easily performed by following a few simple principles. Among these principles include monitoring two sets of conditions:

-

Listen to Your Lubricant

Arguably, more change has occurred related to lubricant analysis and condition monitoring in the past 30 years than all other areas of lubrication. Why does this make sense? The wisest among us know that relentless measurement is a key enabler to forward progress and change. Measurement leads us to awareness and finally to action (tangible…

-

Lubricant-Based Techniques for Condition Monitoring of Non-Circulating Gear and Bearing Systems

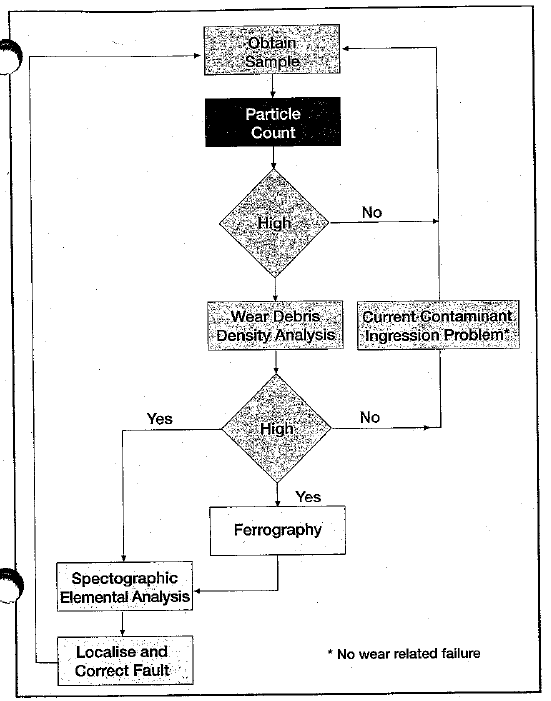

The majority of wear related failures occur as the direct result of particulate contamination. A recent article published in Lubrication Engineering magazine concludes that more than 82% of wear related losses are contaminant induced.

-

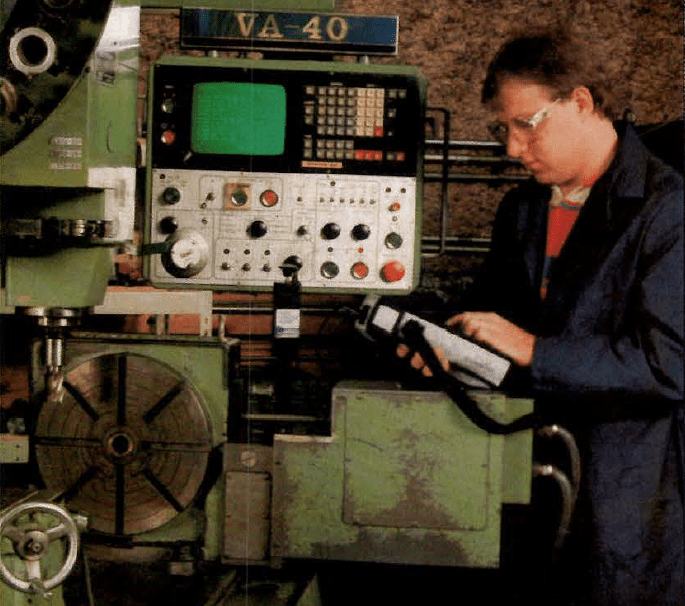

Measure by Measure [oil analysis in machine condition monitoring]

By some estimates, condition monitoring has been around for more than a century, but it is only within the last 5-10 years (and particularly the last 2 or 3) that interest has been at fever pitch.

-

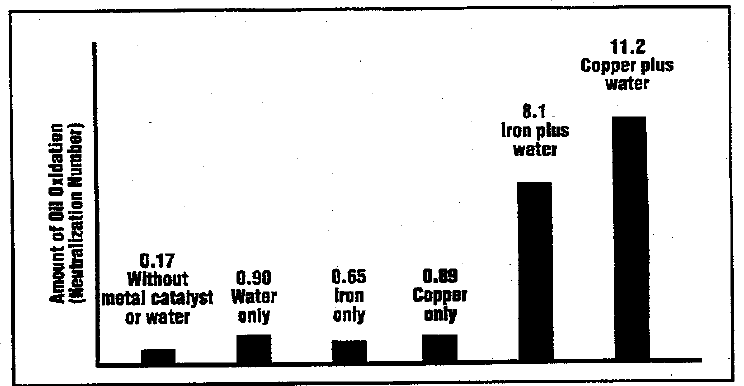

Moisture… the Second Most Destructive Lubricant Contaminant, and its Effects on Bearing Life

Water, once in an oil, is in constant search of a stable existence. _Unlike oil, the water molecule is polar, which greatly limits its ability to dissolve; and many additives have polar extremities which can markedly increase water solubility.

-

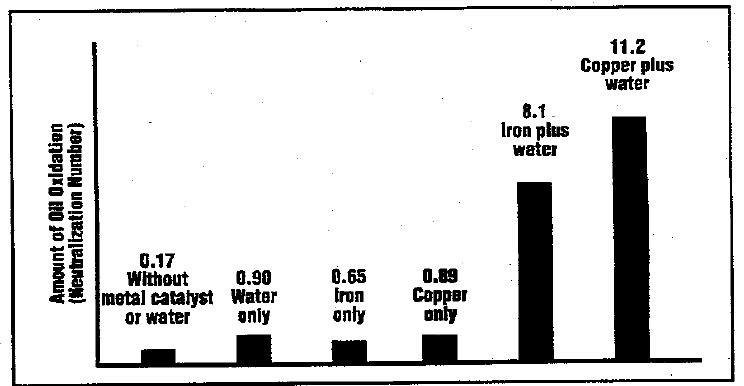

Moisture… the Second Most Destructive Lubricant Contaminant, and its Effects on Bearing Life

Water, once in an oil, is in constant search of a stable existence. _Unlike oil, the water molecule is polar, which greatly limits its ability to dissolve; and many additives have polar extremities which can markedly increase water solubility.

-

Oil Analysis Economics – Saving and Making Money

Changing maintenance from reactive to planned activities is the goal of most compa-nies depending on safe and reliable machinery operation. However, successful change management demands a workable plan. The best plan is one with an eye for what lies ahead – a program that can pinpoint precise maintenance needs. The strategy is sometimes referred to…

-

Oil Analysis Reports – What’s Missing in the Comments?

It is often said that a well-engineered oil analysis program has three essential categories. In the past, I’ve referred to this as the iron triangle of oil analysis. The three categories are:

-

Particle Contamination – 10 Important Things You Should Know

This isn’t your usual article on how important clean oil is to lubricant health and machine reliability. Yes, we are going to talk about particle contamination, but we’re going to take a much closer look at the destructive traits of this nearly invisible material that cohabitates with our lubricants.

-

Proactive Maintenance is a Blueprint for Success

It can take just one breakdown of a critical machine to spin an entire plant into an immediate production halt. At this point, it is too late for the plant manager to do anything but call a service technician, then gasp for air while counting the lost production.

-

Proactive Maintenance is the Cost Reduction Strategy for Diesel Engines and Gas Turbines

The field of maintenance technology is going through a revolution of change. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be maintained to achieve useful operating lives many times that attainable just a few years ago.

-

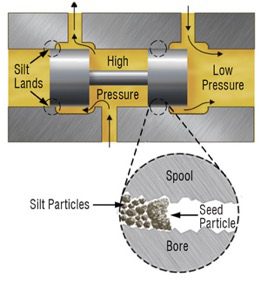

Recognizing the Causes and Hazards of Silt Lock

Do you know about silt lock? This common condition causes motion impediment failure in certain machines. While this type of failure usually doesn’t involve wear or permanent internal damage to the machine, it is sudden and abrupt.

-

Six Questions Every Lube Tech Should Be Able to Answer Correctly

We’ve addressed the virtues of training numerous times on the pages of Machinery Lubrication and other Noria publications. Still today, we encounter a national workforce in the lubrication field that seems largely oblivious to many of the fundamental concepts that embody excellence in the profession.

-

Skillful Out-leakage Detection

This is the most common form of leakage. It is also known as external leakage. Out-leakage relates to a failure of containment. Typically, liquids or gases follow the path of least resistance, going from high pressure to lower pressure. A crack, clearance, orifice or unsealed space becomes the leakage path through which the fluid, gas…

-

Standby Equipment Oil Monitoring and Maintenance

Many lubricants residing in standby equipment have only a few hours of service life. These few hours may be only from occasional scheduled restarts, typically circulating the oil at low load, sometimes barely warming it to operating temperature. In other cases, standby, laid-up and peak-load equipment may sit for weeks or even months without use.

-

The 5 States of Machine Inspection 2.0

When most of us refer to inspection, we are thinking of running machines inspected routinely, say on daily rounds. Unarguably, this type of on-the-run inspection is critical to machine condition monitoring, but other types of inspections are important as well.