-

The Consequences of Forgetting to Perform Preventive Maintenance

Lubrication requires constant attention. Vigilance is perhaps a better word. It’s easy to forget the things we are not motivated to do. Yet, rarely do we forget those activities we are passionate about and desire to do.

-

The Difference Between Good Lubrication and Good Lubricants

Lacking real knowledge in lubrication, companies must still make lubrication decisions. Decisions often seem straightforward on the surface, but below this surface, they are plagued with pitfalls that can cost companies dearly.

-

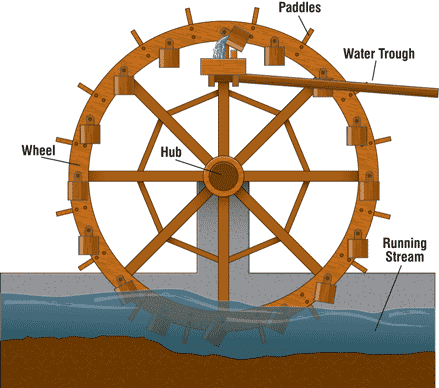

The History of the Noria

The word “noria” comes from the Arabic term, Na-urah, meaning “the first water machine.” It was the earliest mechanical device propelled by means other than man or animal.

-

The Richness of Machine Failure

The definition of an asset is something that delivers future value (such as a machine that produces your widgets year after year). Conversely, a liability is something that can consume your assets in the future (such as negligent or faulty reliability practices). Like an endless string of mortgage payments, the long-term cost of such liabilities…

-

The Six Most Expensive Oil Analysis Tests

Do you know the six most expensive oil analysis tests? Maybe you do and maybe you’ve learned to tolerate them or simply didn’t register their true cost. For the maintenance organization seeking world-class status, you might call these the “tests of fire” because they often separate the winners from the users.

-

The Surface Tension Test – Is It Worth Resurrecting?

In all of my years in oil analysis, I cannot recall a single time when data from a surface tension (ST) or interfacial tension test (IFT) appeared on a routine analytical report, aside from transformer oil analysis, for which the test is considered routine.

-

The Value of Muck Sampling in a Condition Monitoring Program

If you thought oil analysis was only about monitoring oil properties, you’re in for a big surprise. It’s a fundamental premise that we don’t analyze the oil merely to generate data, but rather we are surveying for answers to machine reliability questions.

-

To Flush or Not to Flush

Lubricating oil is the lifeblood of virtually all rotating equipment found in a power plant. Keep it clean and the lube system is relatively low-maintenance. However, cycling operation and restarts after a temporary or long-term shutdown can create a whole new class of what may be unfamiliar problems.

-

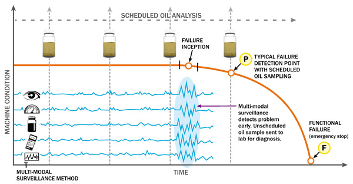

Using ‘Unscheduled’ Oil Analysis for Early Predictive Maintenance

Most oil samples are taken based on a fixed schedule. For large, stationary rotating equipment, monthly or bi-monthly samples are common. Proactive maintenance programs depend on regular checks for oil cleanliness, dryness and lubricant quality.

-

Vacuum Dehydrators Explained and Illustrated

Numerous methods have been developed to selectively remove water and other volatile contaminants from hydraulic and lubricating fluids. These methods include absorbent filter media and regenerable adsorbent packings and the like. In many cases, it is not economical or practical to use disposable media, and as a result, continuous scrubbing processes have been developed. These…

-

Virgin Particles and Weak Signals: Finding Meaning in Wear Debris

I often mention the wear debris universe when I lecture on oil analysis topics. This refers to the extensive array of wear particle technologies and tactics that can help reveal the true tribological condition of a machine.

-

What is the No. 1 Cause and the No. 1 Consequence of Wear?

Particles. Think about it. Tribological studies on wear-related machine failure rank particle-induced abrasion as the No. 1 cause of wear.

-

Which Questions Does Your Oil Analysis Program Answer?

Is the cost of oil analysis really justified? Perhaps you’ve heard another rhetorical question. How long is a piece of string? The answer to both questions is the same – it depends. Oil analysis is justified only when the answers to specific questions about the oil and machine have sufficient value to offset the cost.…

-

Who Should Inspect Your Lubricated Machines?

Perhaps you’ve heard that machine reliability is everyone’s responsibility. In a general sense, this is very true and needed. We should all keep our eyes alert to issues, large and small. We should foster an inspection and proactive maintenance culture. Inspection is largely about relentless and purposeful sensory observation. Any competent and responsible person near…

-

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness.

-

“Superior Sustainability, Taking a comprehensive approach, from production to compliance and beyond,”

In Fitch’s experience, such sustainability assessments hinge on manufacturers being committed co sustainability, not on consumer demand. “In general, I don’t think consumers are clamoring for more sustainable products,” he said, noting that price is a more prevalent concern.

-

12 Lubrication Myths that Need to End

While the lubrication field is rich in folklore, some of these legends are harmful to the progress of lubrication and best practices. These include false claims that lead users down the wrong road to suboptimum or even destructive maintenance practices.

-

Dust Cakes: What Causes Them and Why You Should Care

We’ve all seen them. Perhaps some of us daily. Many take on a certain beauty, almost like a natural cave formation or a work of art. Most have organic characteristics like mosses or algae.