-

Announcing the International Council for Machinery Lubrication

A new non-profit organization called the International Council for Machinery Lubrication (ICML) has been launched to advance causes associated with machinery lubrication in industrial and fleet applications.

-

Aren’t Machines Supposed to Wear Out?

You’ve heard the expression. There are only two things in life that are certain: death and taxes. Some have suggested that the same applies to machinery.

-

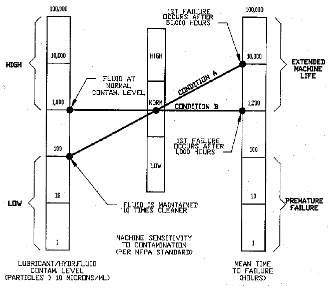

Comparison of Particle Counts Between Eight Commercial Oil Analysis Laboratories

The inclusion of particle counting in the periodic analysis of hydraulic and lubricating fluids has provided an important new advancement to machine diagnostics. With particle counting, machinery users can monitor the principal cause of failure, not just the symptoms, or results, of failure. The benefit, when particle levels are controlled, is extended machine life and…

-

Contaminant Monitoring Targets Root Causes of Machinery Problems

A proactive maintenance approach has been particularly successful in reducing or eliminating one of the most serious equipment maintenance problems: contamination of lubricant or hydraulic fluid systems.

-

Deploying the Invisible Filter

To some contamination control might seem a little like an old tune. After all, hasn’t filtration been around nearly as long as lubrication? And, what’s new that hasn’t already been thoroughly explored and widely applied?

-

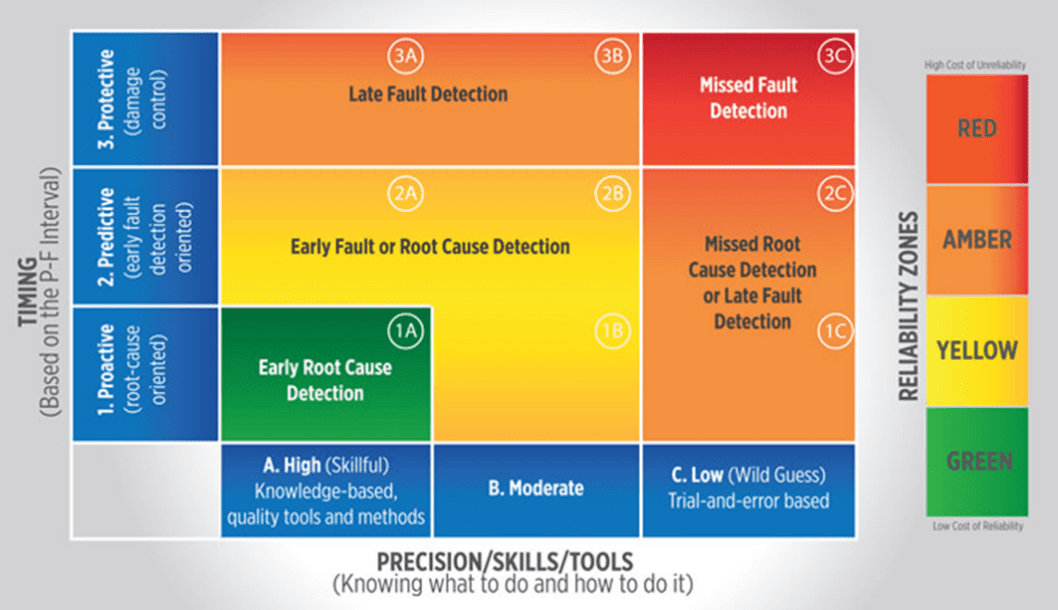

Detection Zone Coding for More Efficient Condition Monitoring

These days, reliability professionals are faced with diverse options related to technologies and methods to detect, troubleshoot and remediate problems. Figure 1 is a simple example of the available options to collect data and arrive at decisions regarding the health of machinery and machine components.

-

Determining Proper Oil and Filter Change Intervals: Can Onboard Automotive Sensors Help?

In recent years, the cost of inappropriate drain intervals to the economy, to the environment and to car owners has received closer inspection. In the United States, the average car owner changes his/her oil at just less than 5,000 miles. Conversely, in Europe the average oil change interval is more than 10,000 miles.

-

Diesel Engine Oil Particle Counting Methods

In condition monitoring, any property that is important to machine reliability and life extension should be a property that is measured, assuming it is technically and economically feasible.

-

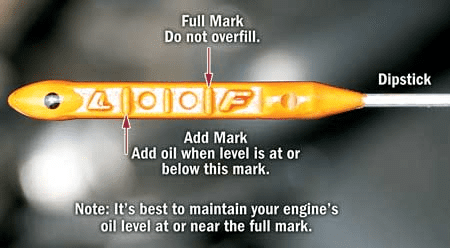

Dipstick Oil Analysis

Dipstick oil analysis may sound a little goofy, but it works. Not to mention it’s also cheap and quick. There’s only one problem – figuring out what the oil on the dipstick really means. No worry. Sit tight for five easy lessons on reading your oil dipstick.

-

Effective Lube Oil Management

The first step in designing a lubrication management program is to have a qualified professional perform a lubrication audit. Its objectives should be to:

-

Establishing and Maintaining Levels of Cleanliness [in Lubricants]

Process plants and manufacturing companies have machinery lubricated by mineral-based or synthetic fluids and other machinery powered by lower viscosity hydraulic fluids.

-

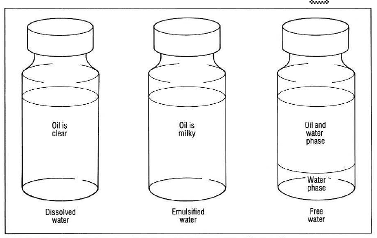

Filtering water from hydraulic oil

Water in a hydraulic system constitutes a serious form of oil contamination. However, water contamination is rarely recognized as such, hardly understood, and, until recently, considered difficult to combat.

-

Filters can Remove Water from Hydraulic Fluid

Here is the latest component for hydraulic system filtration and contamination control Water is a very serious contaminant in oil hydraulic systems. Yet, water contamination is rarely identified, poorly understood, and, until recently, considered very difficult to remove.

-

Fluid Conditioning of Aviation Hydraulic Fluids

This paper discusses the problems associated with hydraulic fluid contamination in aircraft as well as the benefits to be achieved by fluid conditioning. Also discussed is fluid conditioning prior art and the proprietary designed preferred by Diagnetics.

-

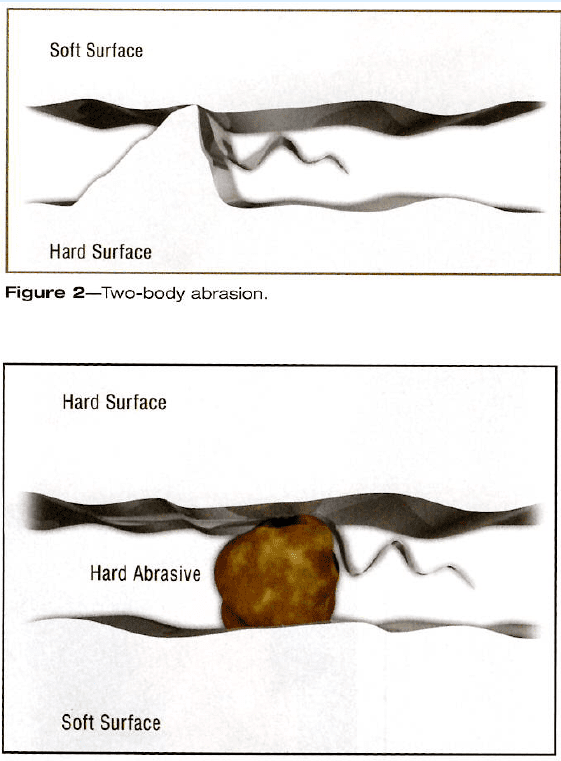

Fluid Contamination Analysis as a Maintenance Tool

Oil contamination can be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial and may even be detrimental to the performance of the oil and/or operating machinery.

-

Headspace Management – Are You in On This Best-Kept Contamination Control Secret?

By now, most lubrication professionals are keenly aware of the reliability gains associated with contamination control. Those who have traveled down this road know that clean and dry lubricants often come at a price.

-

Hydrocarbon Analysis

The aim of this chapter is to briefly present six analytical methods for characterizing hydrocarbon compounds found in fuels and lubricants.

-

In Search of a Definition – What is Oil Analysis?

The term “oil analysis” has been used with respect to lubrication and machine reliability since the 19th century. Yet, over the years I have seen only a few attempts to assign a specific definition to the activity despite its widespread application in industry. Most of these definitions are too narrow or fail to include important…