-

Motor Oil Selection Advice

When it comes to automobiles, people have sharply different motives and objectives. This is reflected not only in the cars they own but also in the way they drive, the fuel they purchase, routine maintenance and general upkeep.

-

Oil Flushing – Let Oil Analysis Guide Your Decisions

This is the fourth and final part in my series on flushing. We’ve already talked about when to flush, the consequences of not flushing, the differences between flushing and oil reclamation, flushing tactics, flushing strategies and flushing sequence.

-

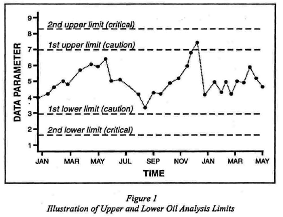

Proactive and Predictive Strategies for Setting Oil Analysis Alarms and Limits

Abstract: In oil analysis, well placed alarms and limits are like trip wires, alerting operators and technicians to an untoward or threatening condition. Oil analysis limits can vary considerably according to machine type, oil type, and reliability goals. This paper discusses four distinct types of limits and how they are applied to different machine and…

-

Proactive Maintenance Can Yield More Than a IO-Fold Savings Over Conventional Predictive/Preventive Maintenance Programs

Plainly stated, the burgeoning cost of maintenance is a serious business problem. According to DuPont, “maintenance is the largest single controllable expenditure in a plant: in many companies it often exceeds annual net profit.”

-

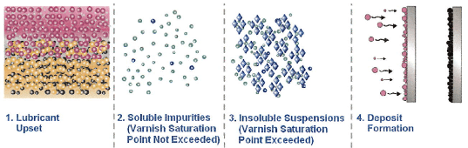

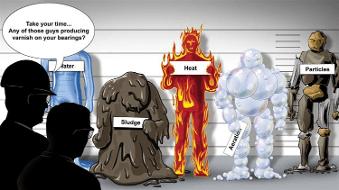

Review of Degradation Mechanisms Leading to Sludge and Varnish in Modem Turbine Oil Formulations

A wide range of fluid degradation and contamination-related issues can affect turbine lube oil systems. One serious and growing concern is the presence of sludge and varnish.

-

Root Cause Analysis for Lubrication Failures

Knowing when a piece of equipment is going to fail (predictive maintenance) is much more difficult than making it last long (proactive maintenance). Even more complex is root cause analysis (RCA) which is performed postmortem, like an autopsy.

-

Sampling Methods for Used Oil Analysis

Sampling is arguably the most important step in the oil analysis process. If the sample in the bottle fails to effectively represent the lubricant and the condition of the machine from which it was drawn, no meaningful conclusions can be from the oil analysis data.

-

Select the Right Metrics for Improved Maintenance and Reliability

Experts agree that the best way to overcome a catastrophic machine failure is not to have one. However, those in the maintenance field understand that machine reliability comes at a price. Monitoring key performance indicators of machine reliability alone may fail to control wasteful and ineffective expenditures that were half-heartedly intended to reduce failure and…

-

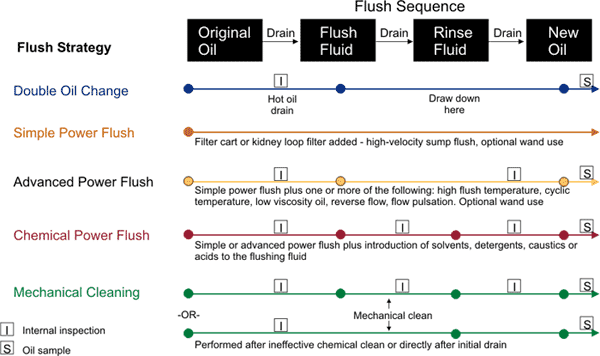

Selecting the Best Strategies for a Successful Oil Flush

This is Part Three of a four-part series on flushing. Part One (May-June issue of Machinery Lubrication) addressed the topic of when to perform a flush and the possible consequences of delaying the procedure.

-

Should New Lubricant Deliveries be Tested?

They are labeled and stored by humans. When it comes to humans, there is one inalterable constant – we make mistakes. Sometimes this is due to lack of vigilance. Sometimes it’s lack of knowledge. It might even be because of indifference.

-

Sight Glass Oil Analysis

Several years ago, when my son was a Cub Scout, his den went on a night hike at our local wildlife sanctuary. He and I went together on this outing. We were led by a professional nature guide who worked full-time at the sanctuary. I wasn’t expecting much; after all, what can one see in…

-

Silent Assumptions of Bearing Reliability

There are several important silent assumptions of bearing reliability. However, before I address these assumptions, some even more basic assumptions and statements of fact must be established.

-

Strategies to Extend Drain Intervals and Reduce Lubricant Consumption

The reasons that lubricants age and need to be replaced periodically are well known. It is true that many of the factors that influence lubricant consumption and oil change intervals are not within the realm of control of most users. However, there are far more controllable factors that many user organizations fail to capitalize on…

-

Ten Things You Probably Didn’t Know About Air Contamination

Anybody who has been in the lubrication field for at least a couple of years has likely been badgered by problems relating to air contamination. Indeed, aeration and foam present many serious reliability concerns which merit immediate attention by machinery maintainers.

-

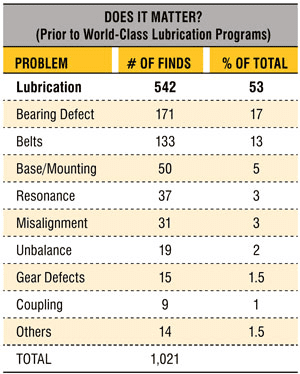

The Business Case for Lubrication Excellence

Machines fail for a reason. They’re not supposed to wear out. Humans are at the root of the vast majority of these failures. It’s also humans that can intervene and restore plants to healthy and sustained operation. This is not an imaginary concept but rather a living reality in a growing number of companies today.

-

The Daily One-minute Inspection

How does this relate to lubrication and maintenance? In my view, the most important maintenance function doesn’t require anything from the tool box. It doesn’t require an instrument or an oil sample. It may not be on your PM schedule or lube route.

-

The Effects of Temperature on Lubricants (Why oil is like an egg)

Hot oil has typically received the most press, even in this publication. After all, oil is not like fine wines that get better over time. In fact, even the very best wine will stress-out when exposed to too much heat.

-

The Enduring Grease vs. Oil Debate

Many who claim to be purists tout that they prefer oil over grease. But then again, there are those die-hard grease advocates who have their own orthodoxy.