-

The Five Cardinal Signs of a Healthy Machine

You cannot monitor your way to a healthy machine just like frequent tests for cholesterol and blood pressure do not make their readings lower. Or do they? Monitoring physical conditions brings vision and awareness to health. It is continuous feedback about how we’re doing. In a similar manner, from measured readings we can report and…

-

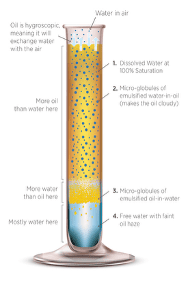

The Four States of Water in Oil

In the last 30 years or so, most of the literature, including Noria’s publications, refer to water as having three states. Free water has been redefined as being water that, by force of gravity, will phase out of the oil. This means it will separate below (most common) or above the oil phase depending on…

-

The Hidden Cost of an Untrained Workforce

Modern organizations call it raising the corporate IQ. Most of us have seen statistics on the lifetime financial returns of a college education. When it comes to education, a penny saved is not a penny earned, but rather green dollars forfeited – hundreds of them, all for the quest of a penny.

-

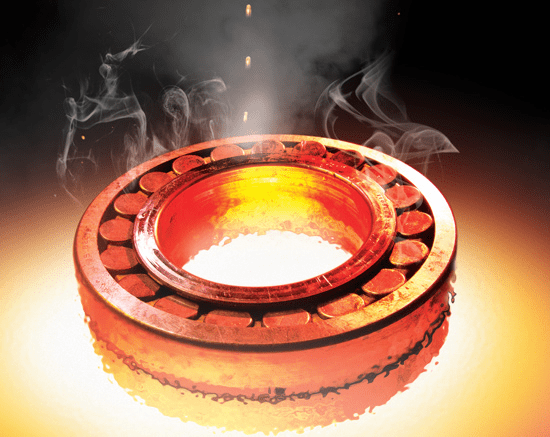

The Hidden Dangers of Lubricant Starvation

For those who strive for lubrication-enabled reliability (LER), more than 95 percent of the opportunity comes from paying close attention to the “Big Four.”

-

The History of Lubrication

In the beginning, man invented machines. One of the first machines, and perhaps the most celebrated invention of all time, was the cart or wagon incorporating the wheel.

-

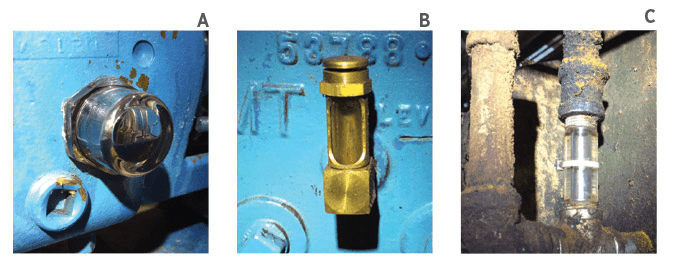

The Most Important Lubrication Inspection: Abnormal Changes in Oil Level

A sudden change in oil level, either up or down, is a telegraphed alert that something is wrong. And, this “something” could potentially be serious. Deferring maintenance or ignoring this alert could lead to a costly repair and longer downtime in the future. The frequent examination of quality oil level sight glasses by trained inspectors…

-

The Seven Levels to Lubrication Excellence

Rome was not built in a day. Transformational change takes time. You’ve heard the expression, “once begun, you’re halfway done.”

-

The Usefulness of Particle Counting in Oil Analysis

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments.

-

These Additives Don’t Exist

I’m afraid I have some bad news … and no, it’s not about the economy. It’s about what I often call “imaginary additives”. These are the additives that seem to exist in the minds of many lubrication practitioners but don’t exist in the physical world of lubrication reality.

-

Three Important Words for Success in Lubrication and Oil Analysis

TRAIN-YOUR-PEOPLE. Using oil analysis to enhance machine reliability is really too simple. Behind the appearances of complexity and vale of high science are the most basic of concepts. We can try to make it difficult, but why?

-

Tricks to Classifying Wear Metals and Other Used Oil Suspensions

The most common methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing. For some users, because of the criticality of the application, all of these screening tests for wear metals are integrated into the routine test slate.

-

Use Lubricant Zone Inspections for Early Problem Detection

Early detection means frequent detection. While daily one-minute visual inspections have been discussed previously in Machinery Lubrication magazine, many questions remain, including where and how you inspect, what the observed conditions mean, and how you penetrate a machine’s exoskeleton exterior without X-ray vision.

-

What is Your Oil’s Impurity-holding Capacity (IHC)?

There has been much said in recent years about the increased propensity of some modern oil formulations to produce sludge and varnish. Ironically, many of the oils accused of contributing to varnish are the same oils endowed with exceptionally high oxidation stability due to advanced refining technology and formulation science.

-

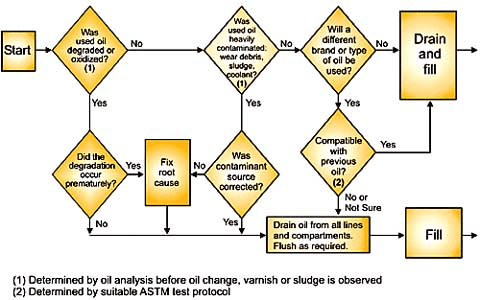

When to Perform an Oil Flush

What should you do when a lubricant doesn’t get a clean bill of health? More specifically, what must be done with the machine that contained a degraded or contaminated lubricant after the oil drain? Is a flush required?

-

Why Inspection 2.0 Is Your Best Strategy for Early Fault Detection

Inspection, in its most basic form, has been around forever. However, like most things in life, what you get out of an activity depends entirely on what you put in. This column is about radical reinvention of the whole concept of machine inspection. It has little to do with conventional practices of doing daily machine…

-

Why Lubricant Supply Contracts No Longer Go to the Lowest Bidder

Though typically treated as a commodity by many, the lubricant is a vital component of the machine. For many organizations, the quality of lubrication is the single greatest factor that influences machinery reliability and productivity.

-

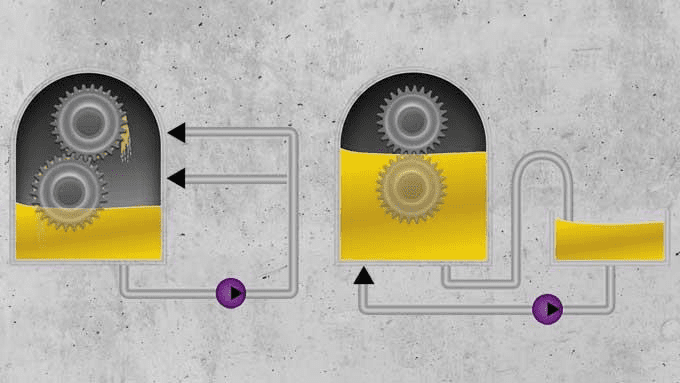

Add Oil Circulation to Gear and Bearing Sumps for Greater Reliability

The designs of many common machine mechanisms have not changed significantly in decades (centuries in some cases). This is especially true where lubrication is involved.

-

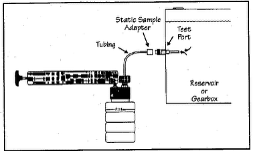

An Introduction to Fluid Contamination Analysis

Oil contamination may be defined as any foreign material found in the lubricant which is not added by design. Usually, contaminants are not beneficial, and may be detrimental, to the performance of the oil and/or the operating machinery.