-

Review of Degradation Mechanisms Leading to Sludge and Varnish in Modern Turbine Oil Formulations

In recent years, there has been an unusually large number of reported cases associated with varnish and sludge formation in turbine-generator and compressor applications using Group II turbine oil formulations.

-

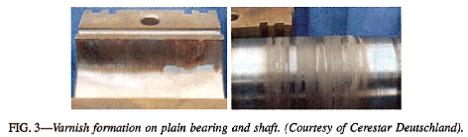

Sludge and Varnish in Turbine Systems

The products of lubricant degradation are called sludge and varnish. These products start in the dissolved form and accumulate until the lubricant reaches its capacity, referred to as the saturating point, forcing any excess to convert into insoluble degradation products.

-

Sludge and Varnish: Two Puzzling Contaminants

Most oil-related problems in machinery lead to wear or corrosion. However, there is one very serious problem – the presence of sludge and varnish – that may cause neither. Instead, these substances plug flow passages and cause valve sticking.

-

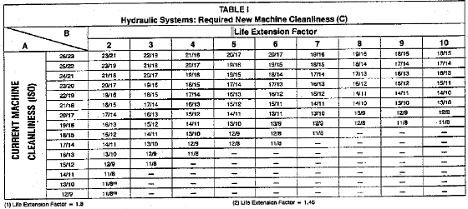

Strategic Implementation and Cost/Benefit of Contamination Control

Contamination control encompasses the subject of machine life and maintenance costs. This paper discusses the Life Extension Method (LEM), a program to extend the meantime between failures based on improved fluid cleanliness levels.

-

Strategies to Achieve and Sustain Dry Oil

Countless times, I’ve devoted this column to stressing the virtues of contamination control. With each passing year, we seem to receive more and more user feedback detailing and validating the business case for clean, dry and cool oil.

-

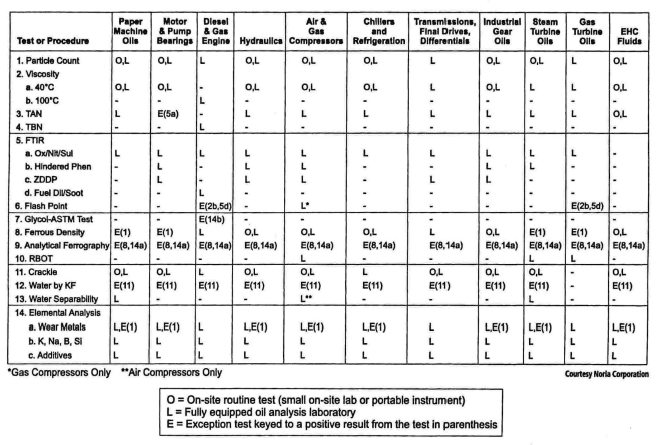

Successful Oil Analysis Practices in the Industrial Plant

Every industrial organization has experienced the consequences of shoddy maintenance: contract penalties, junked parts, injuries, catastrophic damage, ballooning costs, missed shipping dates, irate customers, and sickly quarterly financial reports. Gone are the days when a machine had a predictable service life, after which it was replaced, continuing the cycle. Today, machinery and equipment can be…

-

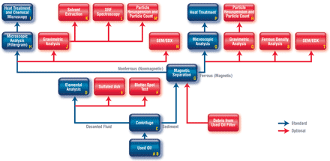

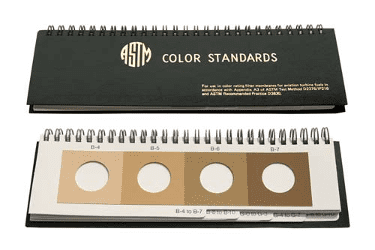

Tactics For Identifying Wear Metal and Solid-particle Suspensions

The most widely used laboratory methods for initial detection of abnormal levels of wear debris in used oils include elemental analysis, ferrous density analysis (DR, etc.), particle counting and patch testing.

-

Taking the Guesswork Out of Filter Selection

y now, organizations that have advanced reliability and maintenance programs understand the intrinsic value of lubricant cleanliness. Noria and many others have published extensively on this subject.

-

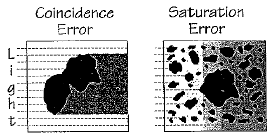

The Accuracy and Reliability of Optical Particle Counters with Industrial Oils and Hydraulic Fluids

Optical particle counters (OPC’s) have a long history of use in industrial hydraulic applications. Traditionally, their success has been limited to scientific laboratories and other highly controlled environments.

-

The Anatomy of a Filter Inspection Report

When the history of the condition monitoring field is written, there will likely be a chapter, or at least a few pages, on the odd paradox surrounding how infrequently use of used filter testing was employed (in the beginning).

-

The Basics of Used Oil Sampling

Proper oil sampling is critical to an effective oil analysis program. Without a representative lube sample, oil analysis cannot be used effectively to monitor oil condition, predict machine failures or help you extend asset life.

-

The Benefits of Using Wear Debris Analysis in Industrial Machinery

The analysis of powertrain lubricants for the purpose of detecting faults and abnormal wear patterns is a useful practice in mobile equipment applications. Unfortunately for many users, these techniques don’t always transfer successfully into stationary equipment applications. In recent years, new approaches and techniques have been advanced to improve the detection of incipient and developing…

-

The Difference Between Good Lubrication and Good Lubricants

I have learned that excellence in lubrication is just as difficult to realize as it is rare to find. The reasons for this are many. One simple explanation is the field of lubrication is a specialty that takes education and years of experience to master – like most professions.

-

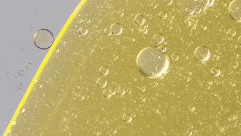

The Hazards of Water Contamination in Oil

Most of us are well aware of the enormous damage water can exact on a machine and its lubricants. However, the magnitude of this potential destruction seems to depend directly on five enabling factors. These factors are listed below and are further diagramed in Figure 1.

-

The Importance of Sustainability for Transformational Change

We’ve all seen change that was well-intentioned and purposeful. Yet most examples of change are not sustained over time and sadly cycled back to the ways of the past. The cause of this seems to resemble a powerful magnet that’s imbedded in every organization.

-

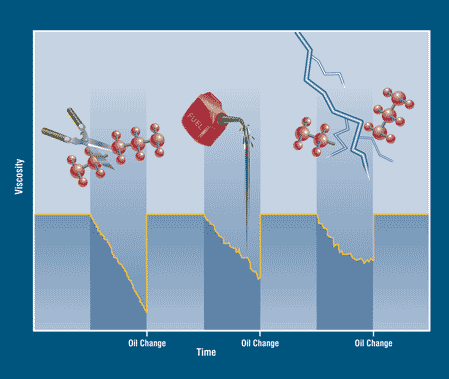

The Meaning of Low Viscosity

Viscosity can go up, down or remain unchanged. The list of root causes that can alter a viscosity reading is quite extensive; hence the reason why viscosity has become such an information-rich measure of used oil condition. After all, when viscosity has not changed, you can rightly conclude that the many known viscosity-altering factors are…

-

The Power of the Patch (Comparing particle analysis methods using membranes)

The practice of transferring suspended particles to the surface of a membrane for analysis has been around for decades. It is perhaps the earliest method for inspecting solid contaminants and wear debris in a used sample of oil. It is of no surprise that these methods have enduring use today. In fact, some are the…