-

Intervention is Key to Machine Life Extension

Try this simple experiment. With notepad in hand, go out into your plant and walk around a sampling of your most critical machines. These are the ones that have high probability of failure and/or the greatest consequences of failure.

-

Justifying the Cost of Excluding a Gram of Dirt [the economics of controlling contaminant ingression)

For years Noria has been saying, “The cost of excluding a gram of dirt is probably only about 10 percent of what it will cost you once it gets into your oil.” Recently, a Noria training client asked us to document proof of this statement.

-

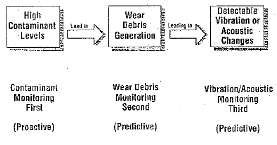

Lubricant-Based Techniques for the Condition Monitoring of Non-Circulating Gear and Bearing Systems

The best maintenance techniques for mechanical machinery are condition-based techniques. Condition-based maintenance is maintenance prescribed by the real-time needs of the machine according to changes in specific operation conditions. These conditions fall into two categories.

-

Managing Reliability in Real Time – The Risk Management Grid (RMG)

In a past article,1 I mentioned that in the world of reliability, risk can be defined as the probability of failure multiplied by the consequence(s) of failure. This simple definition should be a reliability team’s most important daily metric. In this editorial, a two-dimensional matrix is proposed that serves as a real-time moving picture of…

-

Managing the Perils of Short-volume Oil Changes

The term “short-volume oil change” (SVOC) relates primarily to circulating oil systems. An SVOC occurs when an oil change (either scheduled or condition-based) only involves draining and refilling the oil in the system tank or sump.

-

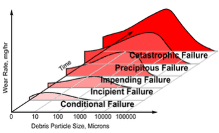

Maximizing Fault Detection in Rotating Equipment Using Wear Debris Analysis

The analysis of power train lubricants for the purpose of detecting faults and abnormal wear patterns is a well developed practice in mobile equipment applications. However, these same techniques don’t always transfer successfully into stationary equipment applications for many users.

-

Model of a Fuzzy Logic Expert System for Real-Time Condition Control of a Hydraulic System

Condition control is defined as the interactive processes of condition monitoring, condition analysis, and condition response. A model is presented which employs the use of expert systems to achieve real-time condition control of a hydraulic system.

-

New Lubrication Commandments – Conserve Energy, Protect the Environment

It seems counterintuitive that lubricants selected to optimize wear control may not be optimum when it comes to energy conservation.

-

Oil Sampling Mistakes to Avoid

I recently received an e-mail from a colleague seeking my opinion about a specific sampling philosophy. Referring to mobile equipment such as excavators, scrapers and dozers, he asked if good oil sampling depended much on sampling location.

-

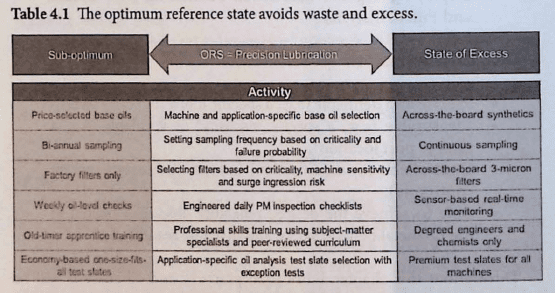

Optimizing Lubrication and Lubricant Analysis

Lubrication is an unmistakably integral part of machine reliability. Rotating machines are dependent on lubrication decisions made, such as which lubricant to use, how the lubricant needs to be applied to the tribological zones, and what is done during operations to monitor and control the integrity of these frictional zones.

-

Origin of Spherical Particles in Lubricants

Spherical particles have been found in microscopic analysis in many different machines. The phenomenon of perfectly round spheres has been a topic of interest since their discovery and a number of theories have been formulated for their origin.

-

Particle Contamination — Both a Cause and a Result of Mechanical Failure

The monitoring of particle contamination in lubricating fluids is a critical indicator of incipient and impending failures. Recent research, under both laboratory and field conditions of the contaminant sensitivity of bearings, reveals a well defined cause and effect relationship between contaminant levels and relative machine life.

-

Performing a Failure Scene Investigation

As head of Noria’s failure investigation group, I’ve led many interesting studies in search of failure root causes and remedies. These include missile system failures, highway accidents, helicopter crashes, and turbine-generator wrecks. Most of these nearly 100 investigations were substantially hampered by errors made in collecting and preserving evidence.

-

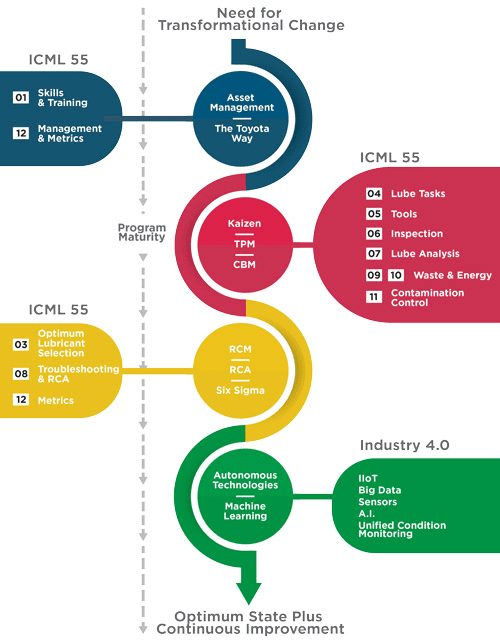

Philosophies of Transformational Change and ICML 55

I first met Ron Moore in the early 1990s. He is known as an icon in the reliability community and is the author of an excellent book entitled What Tool? When? This book tackles a delicate subject that is both difficult and controversial.

-

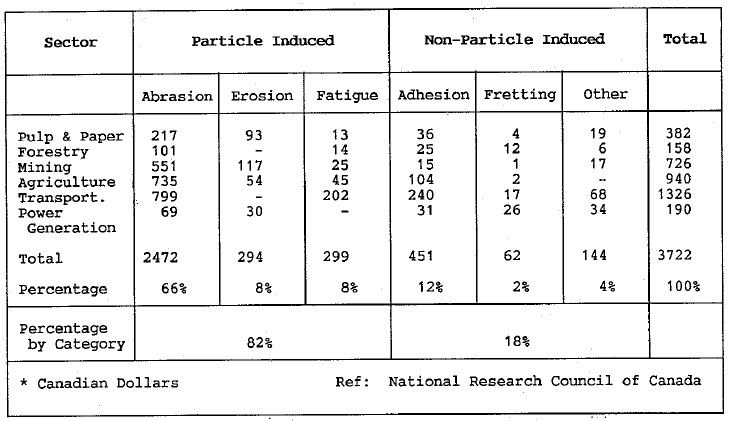

Proactive Maintenance – The New Technology for Cost-Efficient Contamination Controlof Mechanical Machinery

It has been proven that almost all mechanical failures are caused by contamination; hard particle contamination to be ·specific. Once the root cause of machine failure has been defined, a program to correct these failures, extend machine life, and reduce maintenance costs must be developed. Such a program has been developed; it is called Proactive…

-

Quantifying The Contaminant Tolerance of Hydraulic Systems Using the Contaminant Life Index

Users of hydraulic equipment need to know how clean their fluid should be. The information and procedure for determining this has not been readily available in the past.

-

Recognizing the Symptoms of Lubricant Incompatibility

Rule No. 1: Don’t mix incompatible lubricants. Rule No. 2: When in doubt, assume that two lubricants, when mixed, will be incompatible and will exhibit adverse side effects.

-

Remedies for a Bad Maintenance Culture

You may not be surprised to know that most companies need a culture intervention – something like a 12-step program. This column will discuss behavioral issues that are often at the core of a culture of neglect and mediocracy. It borrows much from management science and leadership principles.