-

The Power of Truthful Assessments in Jumpstarting a Reliability Transformation

By Jim FitchMachinery Lubrication Magazine One of the best examples of courage is the man who asks to hear what he doesn’t want to hear. While it’s human nature to fear or dread bad news, the wisest among us will frequently ask for it. Why? Because winners change what losers want to leave the same.…

-

The Role of Lubrication Management Professionals

Thousands of companies around the world have an immediate need to hire lubrication management professionals. These companies are owners of numerous production assets that are critical to industrial processes and fleet operations.

-

The Ten Most Common Reasons Why Oil Analysis Programs Fail & the Strategies That Effectively Overcome Them (booklet)

Many have read the well-documented case studies that convincingly demonstrate the practice of used oil analysis as a sound approach to reduce maintenance and downtime costs. However, for most users, these rewards have evaded their best efforts due to common implementation errors. Like many pursuits in life, there is often a very fine line that…

-

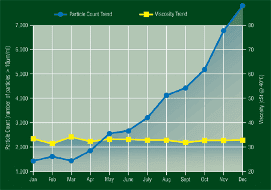

The Truths About Oil Analysis Data Trending

The best way to trend oil analysis data is to follow its movement visually using a standard trend plot. Trending can quickly reveal the rate-of-change over time (slope on the plot) associated with a series of monotonic data points that might reveal a reportable condition.

-

The Wrath of Unscheduled Downtime: Why Oil Analysis is a Wise and Effective Defense

There are 8,760 hours in a year. Few plants manage to produce at full capacity for all of those hours. Instead, there are periodic production stoppages due to tooling changes, product changes, scheduled PMs/inspections and unscheduled downtime (reliability issues). Every hour the plant’s assets aren’t utilized is an hour of lost revenue and profits.

-

Trouble-Shooting Viscosity Excursions

When an oil’s viscosity makes a significant change it is meaningful. The majority of the characteristics associated with wrong, contaminated or degraded lubricants will cause a change in viscosity. Restated, when trending the viscosity of a used oil and no reportable change occurs, one can conclude that many of the things that could be happening…

-

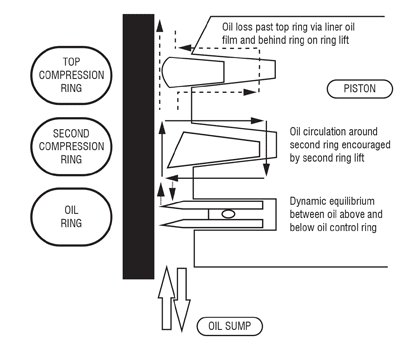

Understanding How Engines Consume Oil

High consumption of engine oil is almost always a symptom or consequence of another condition of even greater importance. This article will address this issue from the standpoint of oil loss through combustion pathways (versus leakage).

-

What Do You Do with a High Particle Count?

In recent years, I’ve been part of numerous investigations relating to expensive machine failures preceded by oil samples that registered high particle counts. Each time I asked the asset owner, my client, why the aberrant particle trends were not investigated further. In most cases the response was that they didn’t think it merited the extra…

-

Why Onsite Particle Counting Makes Sense

With the widespread use of plant-level particle counters, maintenance organizations are becoming more sophisticated and skilled in the management and control of oil cleanliness. This has led to the discovery of a host of new tactics and practices that involve combining the particle counter with other important onsite oil analysis tools and methods.

-

Why Proactive Maintenance is Key for a World-Class Lubrication Program

It is no surprise that those who enter the maintenance field are mechanics at heart. These are people who possess a native love for machinery and the thrill that comes from making broken things run again.

-

Why You Should Inspect Bearing Grease Discharge

There are three opportunities to inspect the state of in-service grease. One is by disassembly (such as by removing the bearing cap), the second is by sampling the grease using a probe (ASTM D7718), and the third is by examining the purge discharge.

-

You Earn What You Learn

2020 will be known as the year when the world was forced to shelter to protect human lives and to stem the spread of a potent, invisible enemy … COVID-19. The dire economic consequences of this virus are affecting us too. Is it possible there is a silver lining?

-

12 Smart Ways to Revive a Neglected Lubrication Program

Having spent nearly my entire career in the field of lubrication, I’ve become increasingly aware that for many companies, the practice of neglecting lubrication has become deeply engrained in maintenance culture.

-

A New Approach to Maintaining Industrial Equipment

Costly particulate contamination slowly degrades and jams machine components causing product defects, shorter machine life., increased production downtime and decreased energy efficiency.

-

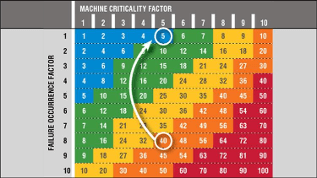

A New Look at Criticality Analysis for Machinery Lubrication

For any given machine, how critical is its reliability? What if it failed suddenly and catastrophically? What would be the consequences – lost production, expensive repairs, fatality? Criticality is the logical starting point for all reliability initiatives.

-

A Well-Constructed Oil Analysis Report

Think of oil analysis as being like the television game show Wheel of Fortune. There’s a message to be told but you’ll only see and understand it if you expose enough letters in their proper order.

-

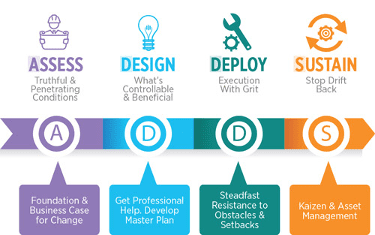

Adopt a New Philosophy—Change

People resist change not because they love the status quo but because they fear the uncertainty of what lies ahead. Yet, without change we are destined to repeat the past. After all, machines that are operated and repaired the same way will tend to wear out and fail the same way. And, for most organizations,…