Category: Inspection

Jim Fitch authored articles & papers

-

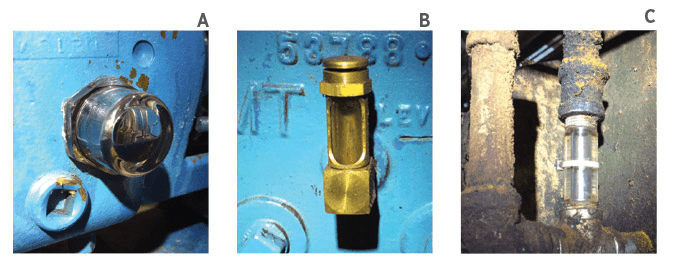

Sight Glass Oil Analysis

Several years ago, when my son was a Cub Scout, his den went on a night hike at our local wildlife sanctuary. He and I went together on this outing. We were led by a professional nature guide who worked full-time at the sanctuary. I wasn’t expecting much; after all, what can one see in… Read More

-

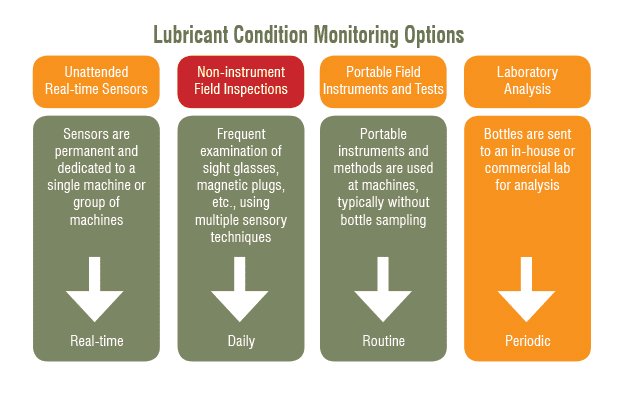

The Daily One-minute Inspection

How does this relate to lubrication and maintenance? In my view, the most important maintenance function doesn’t require anything from the tool box. It doesn’t require an instrument or an oil sample. It may not be on your PM schedule or lube route. Read More

-

The Five Cardinal Signs of a Healthy Machine

You cannot monitor your way to a healthy machine just like frequent tests for cholesterol and blood pressure do not make their readings lower. Or do they? Monitoring physical conditions brings vision and awareness to health. It is continuous feedback about how we’re doing. In a similar manner, from measured readings we can report and… Read More

-

The Most Important Lubrication Inspection: Abnormal Changes in Oil Level

A sudden change in oil level, either up or down, is a telegraphed alert that something is wrong. And, this “something” could potentially be serious. Deferring maintenance or ignoring this alert could lead to a costly repair and longer downtime in the future. The frequent examination of quality oil level sight glasses by trained inspectors… Read More

-

Use Lubricant Zone Inspections for Early Problem Detection

Early detection means frequent detection. While daily one-minute visual inspections have been discussed previously in Machinery Lubrication magazine, many questions remain, including where and how you inspect, what the observed conditions mean, and how you penetrate a machine’s exoskeleton exterior without X-ray vision. Read More

-

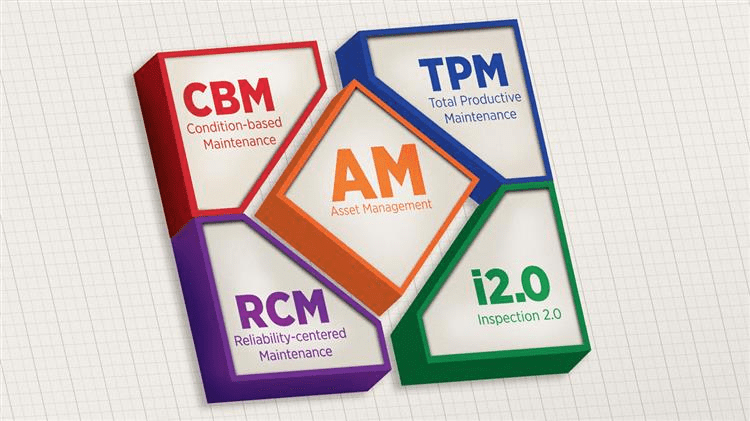

Why Inspection 2.0 Is Your Best Strategy for Early Fault Detection

Inspection, in its most basic form, has been around forever. However, like most things in life, what you get out of an activity depends entirely on what you put in. This column is about radical reinvention of the whole concept of machine inspection. It has little to do with conventional practices of doing daily machine… Read More

-

Diagnosing a Cloudy Oil

Most of us know that healthy lubricants are generally clear and bright. However, as oils age they can lose their luster, and many become dark and opaque. These optical changes are often important symptoms of impending problems that, if occur prematurely, merit further analysis and corrective action. Read More

-

Getting Machines to the Proper State of Inspection Readiness

I have written several articles on inspection recently, as I strongly believe it is foundational to condition monitoring, machine reliability and asset management. My last Machinery Lubrication column introduced the term “Inspection 2.0” to differentiate conventional inspection practices from the intense, probing and purposeful methods needed to optimize benefits. As common as inspection activities may… Read More

-

Guidelines for Developing a World-class Inspection Plan

Like most business plans and strategies, an inspection plan should be built from the top down. It should begin with a clear statement of corporate goals and objectives related to asset management. Read More

-

How to Give Your Machine a Physical

Doctors have perfected the skills of conducting physical exams. They know what questions to ask and how to examine the body for clues that signify health, injury or disease. Read More

-

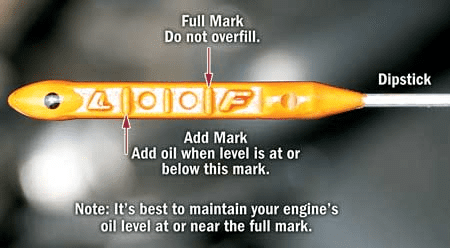

How to Spot Check Your Car’s Oil

Even the very best motor oils cannot safeguard against sludge when free water is present. Within several minutes after starting an engine, the oil typically reaches the thermostat setting. Read More

-

How to Visually Inspect the Health and State of Oil

The well-known KISS principle (keep it simple stupid) was first coined in the 1960s and began widespread use in the U.S. Navy shortly thereafter. While it started as a design principle for engineers, it has since been applied to any activity or creative endeavor that has had the propensity to become unnecessarily complicated. Read More

-

Dipstick Oil Analysis

Dipstick oil analysis may sound a little goofy, but it works. Not to mention it’s also cheap and quick. There’s only one problem – figuring out what the oil on the dipstick really means. No worry. Sit tight for five easy lessons on reading your oil dipstick. Read More

-

Inspection 2.0: The Cornerstone of World-Class TPM

Inspection 2.0 is rooted in some of the most fundamental and time-honored maintenance principles. One of them is total productive maintenance (TPM). Today, it’s hard to play an active role in the field of maintenance and reliability without encountering and embracing TPM. Honestly, it is delusional to think otherwise. Read More

-

Skillful Out-leakage Detection

This is the most common form of leakage. It is also known as external leakage. Out-leakage relates to a failure of containment. Typically, liquids or gases follow the path of least resistance, going from high pressure to lower pressure. A crack, clearance, orifice or unsealed space becomes the leakage path through which the fluid, gas… Read More

-

The 5 States of Machine Inspection 2.0

When most of us refer to inspection, we are thinking of running machines inspected routinely, say on daily rounds. Unarguably, this type of on-the-run inspection is critical to machine condition monitoring, but other types of inspections are important as well. Read More

-

Who Should Inspect Your Lubricated Machines?

Perhaps you’ve heard that machine reliability is everyone’s responsibility. In a general sense, this is very true and needed. We should all keep our eyes alert to issues, large and small. We should foster an inspection and proactive maintenance culture. Inspection is largely about relentless and purposeful sensory observation. Any competent and responsible person near… Read More