-

Filter Flow Rate: The Silent Opportunity

In leading maintenance organizations, managers don’t shrug off the importance of cleanliness. Instead, we are seeing these companies intrepidly improve fluid cleanliness targets over and over in their quest to enhance machine reliability. However, this practice has led to new challenges relating to both the ability to achieve the new targets and the cost of…

-

Five Ways to Monetize Lubrication Excellence Now

For most organizations, the opportunities for a substantial financial win from lubrication excellence are enormous with lots of low-hanging fruit. The most common financial benefit is reduced downtime by averting high-downtime machine failures.

-

Getting Machines to the Proper State of Inspection Readiness

I have written several articles on inspection recently, as I strongly believe it is foundational to condition monitoring, machine reliability and asset management. My last Machinery Lubrication column introduced the term “Inspection 2.0” to differentiate conventional inspection practices from the intense, probing and purposeful methods needed to optimize benefits. As common as inspection activities may…

-

Glycol In Lubricating Oil – Detection, Analysis and Removal

Introducing glycol into lubricating oils exposes your machines to a powerful and poisonous mixture of chemicals. Unlike other harmful contaminants such as water and dirt, the destructive potential of glycol can progress to massive failure of machine components in a narrow window of time.

-

Grease Dry-out: Causes, Effects and Remedies

One of the main disadvantages of using grease over oil is the annoying tendency of grease to cake and dry out. We all know that oil has a natural tendency to drain out of the grease thickener over time.

-

Guidelines for Developing a World-class Inspection Plan

Like most business plans and strategies, an inspection plan should be built from the top down. It should begin with a clear statement of corporate goals and objectives related to asset management.

-

How and Why Machines Wear Out

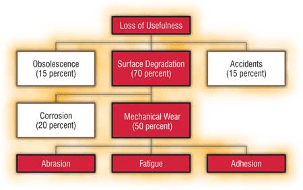

According to Massachusetts Institute of Technology professor emeritus and luminary tribologist Ernest Rabinowicz, there are three things that cause machines to lose their usefulness: obsolescence, accidents and surface degradation. Without question, obsolescence is fundamental to the evolution of engineering and technology.

-

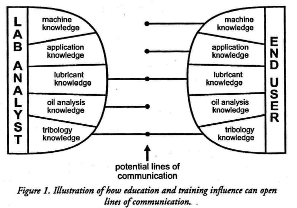

How to Develop a “Win-Win” Relationship With Your Oil Analysis Lab

Turning an oil analysis program into a feisty profit center is well within reach of today’s modern maintenance organizations. In fact, it is commonly achieved.

-

How to Give Your Machine a Physical

Doctors have perfected the skills of conducting physical exams. They know what questions to ask and how to examine the body for clues that signify health, injury or disease.

-

How to Make Your Oil Analysis Program Produce More Alerts

I want bad news fast. Why? Problems tend to compound. Rarely do they heal themselves. Instead, the worse things get, the faster they get worse. As time passes, the cost of repair and lost production can soar exponentially.

-

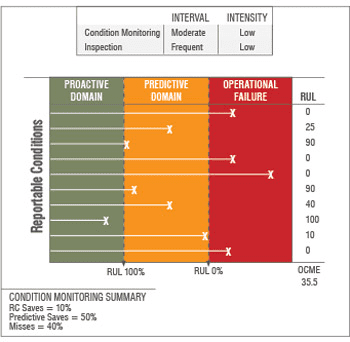

How to Measure the Effectiveness of Condition Monitoring

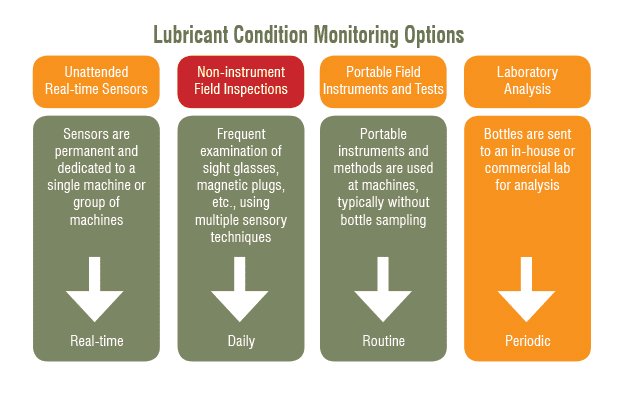

Condition monitoring should never be limited to a single technology or method. Instead, it should combine and integrate an optimum selection of purposeful tools and tasks. Condition monitoring can be largely technology based but can also be observation or inspection based.

-

How to Optimize the State of Lubrication

I remember my first day at a new job in 1981. This is the job that launched me into a 32-year career in lubrication. My first assignment was to conduct a telephone survey of industry professionals on various topics related to oil analysis and contamination control.

-

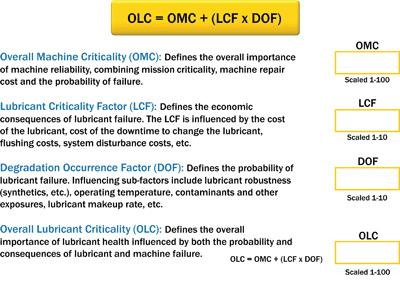

How to Select Machines for Oil Analysis

By Jim FitchMachinery Lubrication Magazine A few years ago, someone mentioned to me that many of his machines were not good candidates for oil analysis because they used little oil that wasn’t worth saving. He added that by the time you flushed the sampling port and pulled a proper oil sample, you’ve almost done an…

-

How to Spot Check Your Car’s Oil

Even the very best motor oils cannot safeguard against sludge when free water is present. Within several minutes after starting an engine, the oil typically reaches the thermostat setting.

-

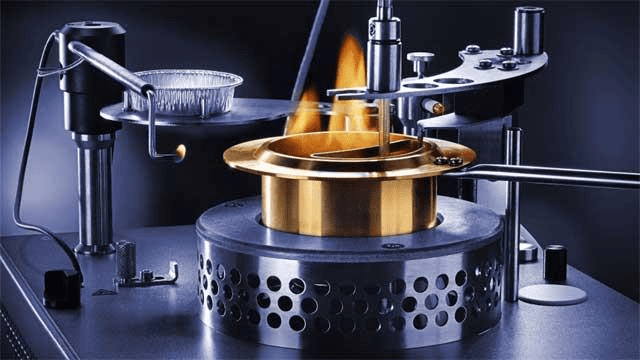

How to Test Flash Point

Like viscosity, the flash point test has always been a standard part of a lubricant’s specification. And, because of its low cost, simplicity and versatility, the test is popular among the used oil analysis community as well. Most commonly used as a quick pass/fail test for fuel dilution, more applications have surfaced in recent years.…

-

How to Visually Inspect the Health and State of Oil

The well-known KISS principle (keep it simple stupid) was first coined in the 1960s and began widespread use in the U.S. Navy shortly thereafter. While it started as a design principle for engineers, it has since been applied to any activity or creative endeavor that has had the propensity to become unnecessarily complicated.

-

How Water Causes Bearing Failure

By Jim FitchMachinery Lubrication Magazine It takes only a small amount of water (less than 500 ppm) to substantially shorten the service life of rolling element bearings. There is a vast amount of research that supports this. Being a career-long crusader of clean and dry oil, I will certainly not argue the contrary. In fact,…

-

Insider Tips on Managing the Costs of Lubricant Filtration

There is a price tag for removing dirt from oil. For large plants and fleets operating in dusty environments, the cost can be substantial – hundreds of thousands of dollars per year.